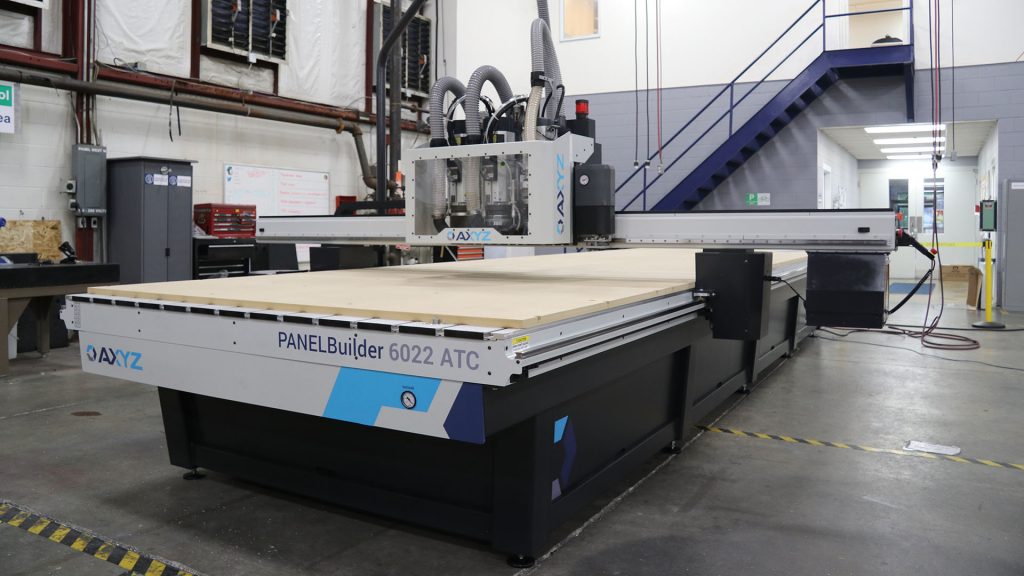

They say “timing is everything” for a good reason. Missing out on profitable business opportunities is something you want to avoid or you’ll live to regret it for a long time. This holds especially true for fabricators of exterior panels. According to a recent study, the global cladding industry is expected to increase to $111 billion by 2025, boosted by the insurgence of using lightweight materials for energy cost savings and programs like LEED certification. So, if you’re not already manufacturing exterior panels, you might want to start considering it. In a growing market like the cladding industry, there is a great amount of opportunity in panel fabrication. Where to start? Consider the new AXYZ PANELBuilder – an all-in-one solution for emerging business in the cladding industry across the globe. Combined with easy-to-use software, the PANELBuilder will catapult your business into exciting new territories, increasing productivity and ultimately, the bottom line.

REDESIGNED FOR OPTIMAL PROCESSING

The new PANELBuilder looks different, but delivers the same quality functionality. Designed specifically for processing large volumes of ACM/MCM/HPL and Fibre Cement Board sheets in the fastest, most efficient way possible, the PANELBuilder can be configured to suit your exact needs. Choose process areas from:

- 72” x 216” (1,842mm x 5,486mm) – Standard configuration for basic panel fabrication.

- 72” x 408” (1,842mm x 10,363mm) – Higher throughput achieved with a pendulum processing system.

- 84” x 216” (2,133mm x 5,486mm) – Ideal for fabricators of high-pressure laminates.

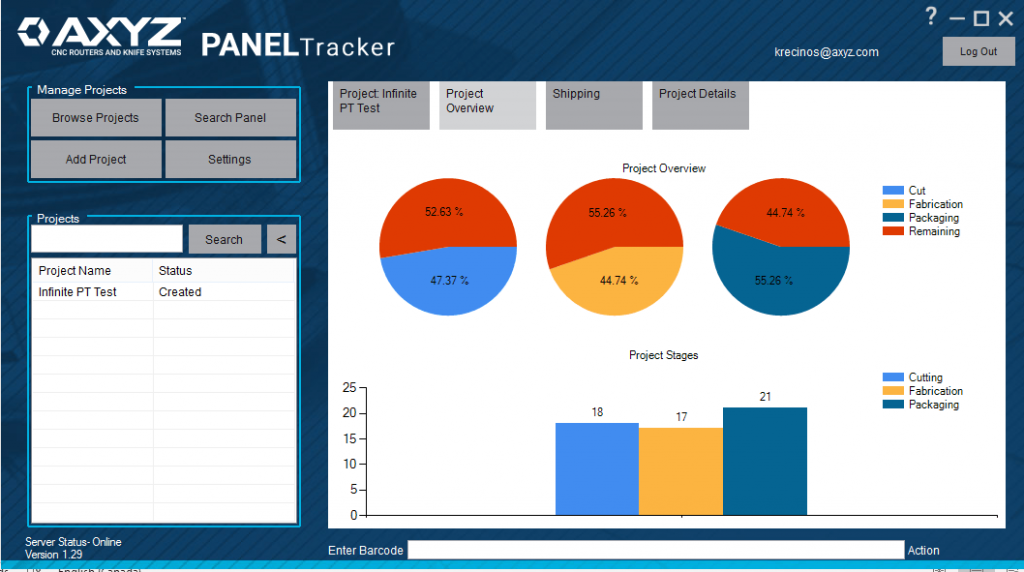

EXCLUSIVE EASY-TO-USE SOFTWARE

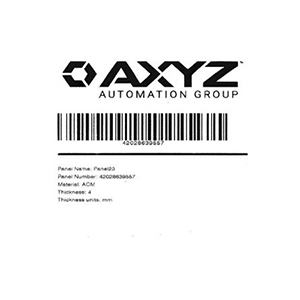

Integrated with the redesigned PANELBuilder solution is the new PANELTracker Management System. Outfitted with the Automated Label Printer (ALP), the printer quickly generates labels which are then applied to individual panels. This eliminates valuable time wasted on manually writing product codes or misidentifying panels as they move through manufacturing. Labels are then printed and applied directly to the panel, reducing inefficient processes and lowering production costs.

Existing CAD users will be happy to learn that PANELBuilder software incorporates easy-to-use CAD/CAM software allowing flexible nesting, automation and machine programming functionality. Combine this with the optional Cordless Barcode Reader, and you’ve got an all-in-one solution specifically designed for the panel fabrication industry.

PANELBuilder Options & Features:

Automated Label Printer

Cordless Barcode Reader

Sample Label

INCREASING EFFICIENCY MINIMIZES CARBON FOOTPRINT

Equally as important and time-sensitive is PANELBuilder’s ability to improve production efficiency through eco-friendly initiatives. If reducing your carbon footprint is a priority, you’ll appreciate how it automatically stores leftover sheet remnants that you can use for future jobs, or automatically cuts extra copies of commonly used parts in any leftover areas of a sheet, as ‘filler parts”. This makes it a more cost-efficient process as it decreases the cost per panel. It also maintains a library of standard material types and sizes, automatically updated globally as well as on a project basis. This ensures you always have the right types and quantities of material available at all times.With its redesigned aesthetic, enhanced options and same high-quality performance, the newly designed PANELBuilder continues to be the number one solution for panel fabricators everywhere.

FOR MORE INFORMATION

For questions about the PANELBuilder, contact a member of your local customer care team or fill out our online contact form.

For PANELBuilder accessories and options, visit CNCshop.com and check out our latest promotion.