Do you keep track of your ACM panels by marking them with a sharpie or manually affixing labels? Or perhaps you’re using costly inventory software that’s not integrating well with your PANELBuilder machine? If this is your struggle, then you need the PANELTracker Management System, part of the latest PANELBuilder solution. It’s simple to use and quickly keeps tracks of all your panels as they move from one stage of production to another. If saving time and money is important to you, then the PANELTracker system is the only project management tool you’ll ever need.

AN ALL-IN-ONE SOLUTION

PANELTracker comes bundled with the PANELBuilder software that is included with the latest PANELBuilder CNC machine. In order to use it, you’ll need:

- Windows 7 PC (or higher)

- PANELBuilder Software Upgrades

- 2D Barcode Reader

- Automated Label Printer

PANELBuilder Version 19

2D Barcode Scanner

Automated Label Printer

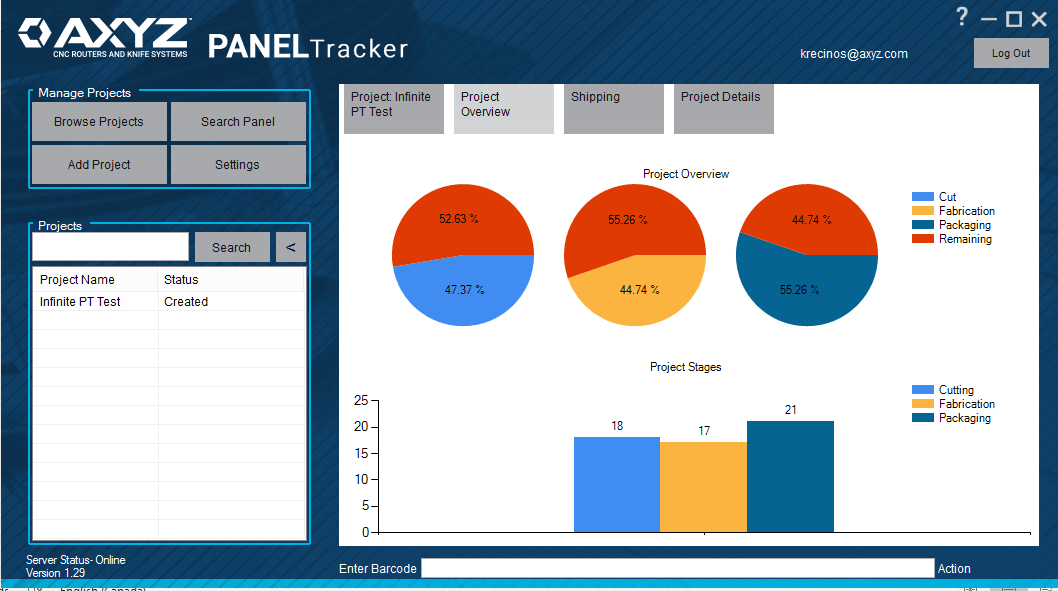

HOW IT WORKS

The PANELTracker works in conjunction with the PANELBuilder software, designed for two types of users:

1. Project Manager, who creates the projects.

2. General User/Operator, who scans the panels.

The system involves 4 key processes:

1.Project Creation

The Project Manager creates the project using the PANELBuilder software. This is where the panel shapes are designed and cut, according to customer specifications. Once this is complete, the data file is exported into the PANELTracker system.

2. Cut

The Operator uses the NC file generated in PANELBuilder to cut the panels on the AXYZ CNC Router. The RPD file is then imported into PANELTracker to create a project. Next, the panels are scanned and marked as “cut” in the system, and the project is updated.

3. Fabricate

Once the panels are cut, the Operator will add hardware to the panels. The panels are scanned again and marked as “fabricated” in the system. The project is updated with this new information.

4. Package/Ship

Finally, the Operator will prepare the panels for shipping. Panels are scanned, the project is updated and the panels are now identified as “packaged”. On the day of pickup, the Operator will generate a packing slip for the packing crate, where the panels are stored. The Operator will use PANELTracker to update the status of the crates as “shipped”.

Done! From production to packaging and finally shipping – keeping track of individual panels has never been easier!

ADDED BONUS

At any point in the process, you can scan a damaged or defective panel. This will:

1. Send an email to the Project Manager with the details of the damaged panel. This also identifies where the damage occurred in the 4-step process.

2. Send the single part .NC file, so the panel can be easily reproduced.

The PANELTracker simplifies the panel tracking process for all PANELBuilder customers. It’s an automated solution that is as cost effective as it is production efficient. Exclusive to AXYZ – there’s no other inventory tracking system like it.

NEED MORE INFORMATION?

Contact a Sales Rep to ask questions about PANELTracker or any other feature of the new PANELBuilder. For parts and accessories, visit CNCShop.com and take advantage of our latest promotion.