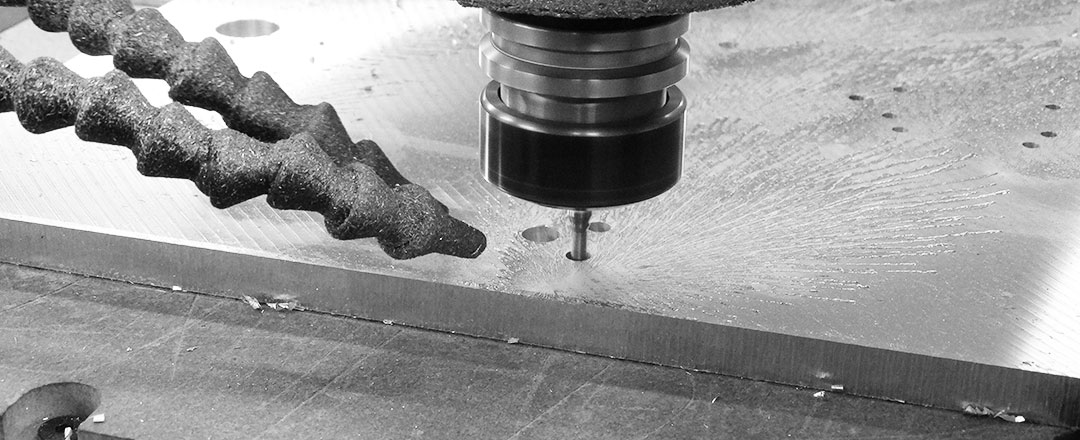

When machining aluminum and other non-ferrous materials, it’s common for parts to come out looking a little rough around the edges. Not the result you’re looking for? Try using a lubrication/coolant system that attaches to your CNC router, like the AXYZ Unist Mister. This system easily mounts onto the back of the carriage and can be retrofitted to almost any machine. It operates with more precision and reliability than any other dispensing system you’ll find on the market today. By using a continuous output of a micro-fine lubricant mist, the AXYZ Unist Mister provides a better cut finish and longer tool bit life.

ELIMINATE UNWANTED BUILT-UP EDGES (BUE)

If you’re new to CNC machining, then you’re probably not familiar with the term “built-up edges” or BUE for short. This is when the material is built up around the tip of the tool, separating it from the chip. Results can be a low-quality edge finish as well as modifications to the design of the part itself, due to the changing geometry of the cutting tool. When using the Unist Mister, it’s easy to prevent BUE from occurring. You’ll also get less buildup under the surface of the material, resulting in clean edges every time.

USE THE AMOUNT OF LUBRICANT YOU NEED

Not all materials require much lubricant or coolant. Depending on the application, the mister can be set to supply the right amount to the tool by:

1. Increasing or decreasing the amount of lube or airflow using the adjustment screws. This combination has enough adjustment to deliver either a fine or heavy mist of liquid to the tool.

2. Manually turning on the mister using a switch on the side of the unit. This allows the mister to be activated during a machining operation, using lubricant only when required.

Choose from two types of lubricants:

1. Regular AXYZ Mister Lube – ideal for regular aluminum processing where welding of parts is not required.

2. AXYZ Clean Cut Cool Lube – leaves minimal residue, making it the best option for applications where parts need to be welded after cutting.

TIP: SAVE YOUR SACRIFICIAL SPOIL BOARD

If you need to use a large amount of lubricant, place an additional sacrificial board on top of your machine’s sacrificial spoil board. A thinner ¼ inch MDF is ideal, as you can easily throw it away or recycle it after use.

SEE THE DIFFERENCE

Here’s a video demonstrating the difference between processing aluminum wet (with lubricant) and dry (without lubricant).

USE THE MISTER WITH:

The Automatic Tool Changer – No operator involvement required! The tool changer automatically selects the correct tool according to those defined in the program, finishing the job as quickly as possible. When used with the Unist Mister, you can preset which tools will be used with lubricant and which ones without.

Questions?

For more parts, accessories and router options, visit CNCShop.com and take advantage of our latest promotion. For information about any of the AXYZ routers, call your local sales team or fill out our online contact form.

For applications where you need to cut thicker sheets of aluminum or require a no heat affected zone (HAZ), look into waterjets for processing heavier metals. Visit WARDJet.com for more information.