If you’re in the business of making signs, you may already have a vast array of tool bits that you use for clean cuts and finishes. If your tool box doesn’t include the O flute bit, then you’re missing out on what other industry leaders are calling the “tool of choice” for sign-makers. In this week’s Tech Tip, you’ll understand why it’s the favourite tool bit for sign-makers across the globe.

What is an O flute bit?

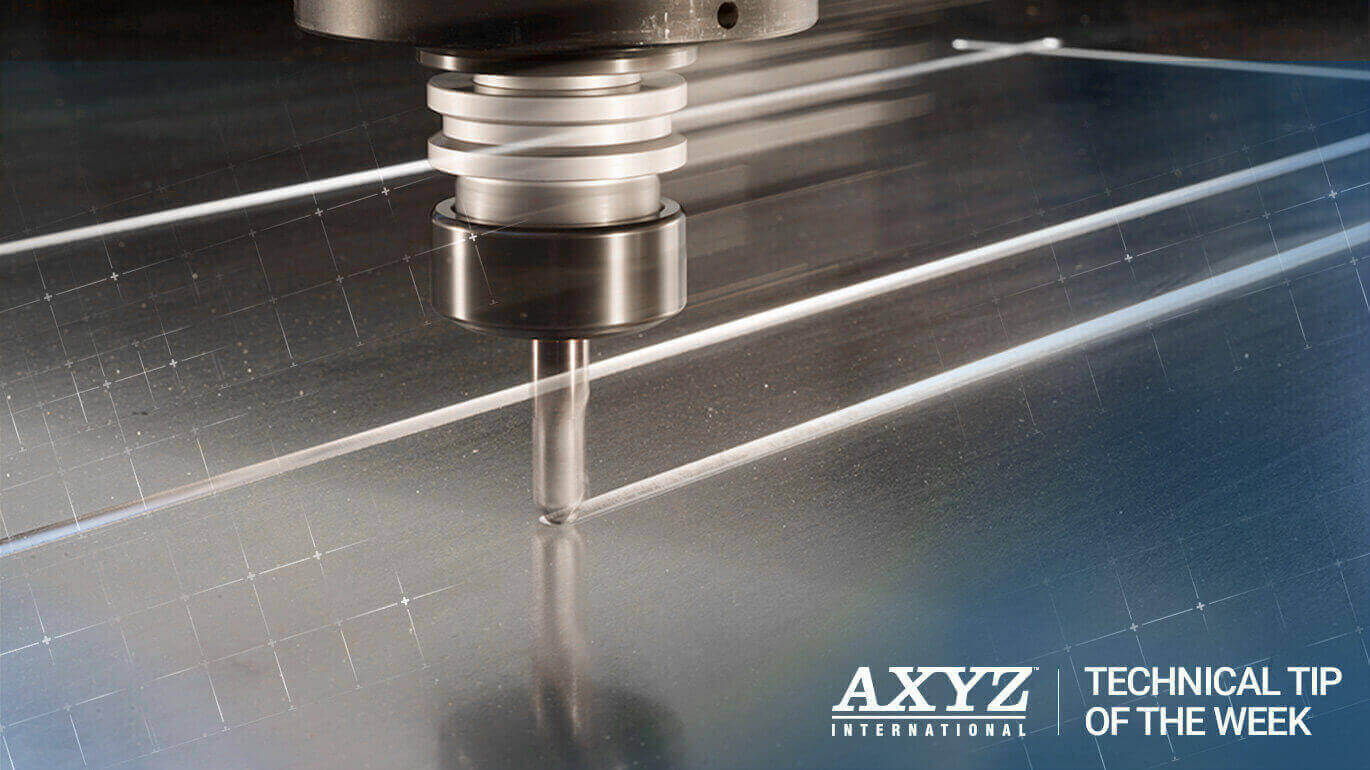

The O flute bit is a carbide spiral flute that features a unique mirror finish, resulting in high quality surface finishes, clean professional cuts and prolonged tool life.

How does it compare with other flute bits?

The O flute bit was manufactured specifically for CNC Router machines for use in a variety of applications. Over the years, due to continuous improvement in its design and geometry, these router bits became the sign-making industry’s favourite tool, easily out shadowing its competition. Compared to other flute styles, the cuts are cleaner, plunges are deeper and chips are easily directed up or down, depending on the type of spiral you choose. If you work primarily with plastic or aluminum, you’ll be happy to learn that heat is dispersed more easily with the O flute bit and it stops weld back.

What material does it cut with?

Although it’s most commonly used with plastic and aluminum, you can use the O flute bit on a variety of material, such as acrylic, nylon, foam board, laminate, solid surfaces and wood. If you have questions about a specific type of material or need more information about the O flute bit, contact your local Customer Care team.

You may also find it useful to read CNC Routers – A Simple Guide to Selecting the Right Configuration For Signmaking.