Why V-Carving?

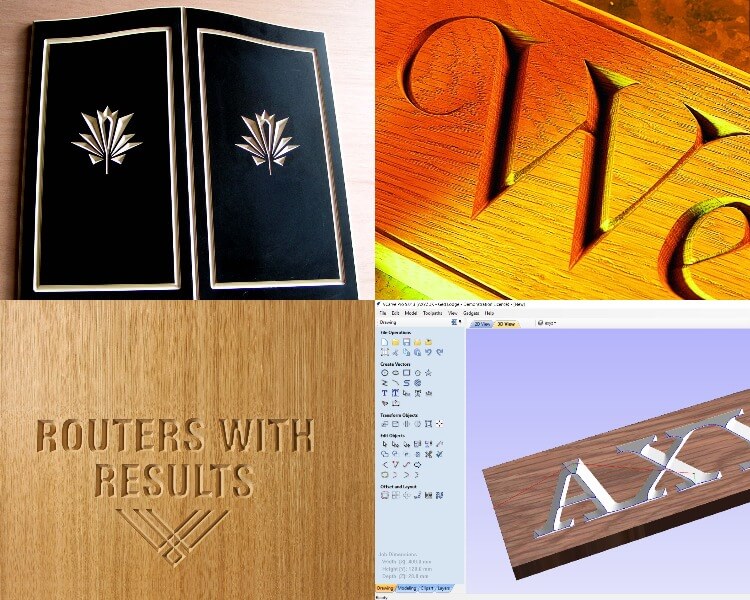

V Carving is a fast and easy way to create great looking signs and other products. Unlike full 3D machining V Carving is fast – it doesn’t require multiple passes and the results are very impressive. The simplicity of V carving is what makes it attractive. All you need to supply is a 2D design and the software will do the rest.

Here are 5 tips for successful V Carving:

- Software: many CAD/CAM systems have the ability to create V carving programs. We recommend VCarve Pro from Vectric which has dedicated features and is easy to setup and use. Data quality is important. Check that your software can produce smooth curves and arcs otherwise the machining operation will be slow and of poor quality.

- Tooling: When using a V bit the angle and tip width have most effect on the outcome. The steeper the angle the deeper the cut will be. A 60 degree V bit is generally a good one to use and will give good depth showing plenty of detail. If your text has very wide stroke widths you may need to restrict the depth of cut in the software. If your V bit has a flat tip this will be evident at the bottom of all cuts. It will also reduce the corner sharpening effect. Single fluted V bits with a point at the tip generally give more pleasing results that those with a flat tip.

- Materials: You can do V carving on pretty much any material that can be routed. Woods, plastics and aluminum all look good but you should test your V-bit first on any new materials to check how deep you can cut in a single pass and determine suitable feed rates. V carving does tend to look good when used on organic materials such as natural wood where the grain will show throughout the cut.

- Fonts: choice of font will have a big effect on the final outcome. Fonts which have varying stroke widths will result in different cut depths. Try serif fonts for a nice decorative effect, the wider the stroke width the deeper the cut will be. This can also be set in the software. Fonts which have constant stroke widths will be cut to a constant depth and any internal corners can be sharpened depending on your tool geometry. If you’re not sure what font to use Times New Roman would be a good one to start with.

- It’s not just for text: V carving can be used to produce many different types of decorative effect, not just for text. Simple corner sharpening can bring an otherwise flat pattern to life. Experiment with different designs and tooling and use the software’s simulation feature to see what it will look like before cutting on the machine.