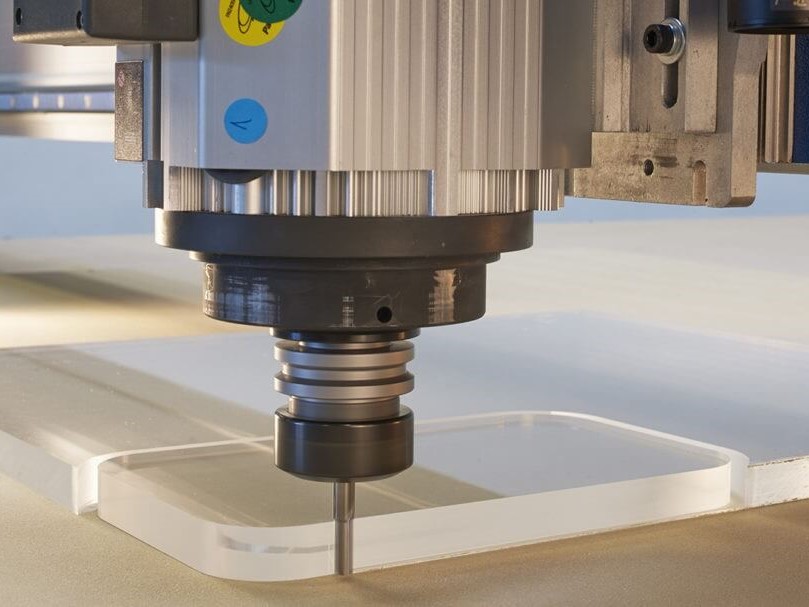

This is the third installment in a four-part series on how to avoid bad cut edges when using CNC routers. The first article, “Plastics Fabrication: How to Avoid Bad Cut Edges When Using CNC Routers,” was published in the December 2017/January 2018 issue and focused on machine fundamentals. The second article, “Avoid Bad Cut Edges: Vacuum Beds and Machine Hold Down,” was published in the February/ March 2018 issue and described poor quality cut edges issues related to vacuum beds and machine hold down. This article explains why choosing the right cutter for the job makes all the difference between getting a jagged, rough, frosty cut or a nice, smooth, clean cut. The cutter may be a small piece of the machine, but it’s the piece doing the hard work and is one of the most important parts when it comes to cut quality.

Get specific

It’s important to recognize that while a cutter may work well with one type of material, it might not always be the best choice for others. In fact, there are cutters specifically designed for certain materials. Typically, these cutters last longer and perform more effectively than general purpose cutters.

The main issue with using a cutter not specifically designed for use with the material is in the quality of the edge cut. There are many applications where that edge will be seen, such as in retail environment display stands. In these instances, it’s important to achieve a smooth, clean and shiny edge versus one that is frosty, untidy and rough. In fact, when working with acrylic, if the wrong tool is used, the cut may result in a rough finish with ripple marks. The modifications in specifically designed cutters can make a substantial difference in their cut quality.

Choose the perfect cutter

Use these tips for selecting the perfect cutter for the job:

Rely on your supplier

Talk to your CNC router supplier for advice and expertise on which tool to choose. If the supplier has a local presence, visit the office and ask the supplier to test the material in question with several tools to determine the best one for the job.

Cheapest isn’t always the best

The saying “You get what you pay for” is true when it comes to cutters. A less expensive tool may work adequately for a little while, but usually it won’t last long. Instead, focus on selecting the right tool for the job instead of focusing on the cost of the tool. Cutters designed for specific materials last longer than general cutters.

Tool fit

Whether the tool is changed manually or through a semi-automatic or fully automatic tool changer, it’s important to keep the collets and locknuts clean and free of dust and chips. Otherwise, the tool won’t be straight during the cutting process, decreasing the quality of the cut edges.

Match the tool size for the job

In general, use the largest tool possible for the design being cut. Bigger tools are stronger and more rigid, which means they won’t bend or deflect when cutting. Smaller tools are needed for cutting fine details on parts and for cutting sharp, tight internal corners. For the best cut quality, use a larger-sized tool to do most of the cutting, and then use a finishing tool to take a very fine amount of material off the part at the end of the process. While this two-stage procedure increases the cutting time, it creates better results than a single cut and has the effect of polishing the part during the cutting process.

Upcut versus downcut spirals

The general recommendation for cutting plastics is to use single flute, upcut spiral cutters. Upcut spirals eject dust and chips upwards out of the cut which reduces heat build-up, extends the life of the tool and produces cleaner cuts. However, when cutting thin, flexible plastics, the recommended cutter is a single flute, downcut spiral one that pushes the material down onto the bed and prevents movement and poor quality of the cut edge.

Keeping cool

When cutting softer materials, there can be issues with heat buildup and a tendency for the material to stick to the cutter. The solution is to use a cold air gun to direct a jet of cold air at the cutter, keeping it cool. Not only will this result in better quality cutting results, but it also helps prolong the life of the cutter tool.

Speed and sharpness

The speed used to cut through the material and the rpm at which the bit is run are critical to achieving a good finish. CNC router suppliers can provide advice as to the appropriate settings for cutting specific materials. Additionally, cutting tools must be sharp to produce a clean cut. As a tool is used, it will wear and its performance will gradually deteriorate. When you are looking for the best possible finish, always use a new router bit.

Ask the experts

Choosing the correct cutter for the job can be a confusing and time-consuming process because it can involve testing a multitude of tools on a variety of materials. A more effective method for selecting the right cutter is to partner with an experienced CNC router supplier. An experienced supplier is one who has invested the time to test available cutting tools to determine the best tool for cutting specific materials. These suppliers have many years of experience cutting all types of materials and recognize that the best tool for each type can come from different manufacturers. They also have qualified application specialists to provide guidance regarding the choice of cutting tool and related machine settings. Tap into this knowledge and expertise for questions and assistance with choosing and using the correct cutter to achieve the best cut quality.

Part four of this series will focus on using programming strategy and data quality to achieve the best cut quality.