In the world of CNC machining, the opportunities to create products for commercial or residential use are endless. From custom finishes on tricky to use vinyl applications to 3D multi-purpose graphic displays, a router gives you both the quality and quick turnaround that is hard to replicate by even the most skilled craftsman. For panel builders using Aluminum Composite Metal (ACM), quality and speed are critical factors to success. This is why leading fabricators around the globe are using the AXYZ PANELBUILDER system. Whether you’re looking to expand your business or you’re a specialist in the cladding industry, the PANELBuilder gives you a high return on investment while meeting the high standards you expect from an AXYZ product.

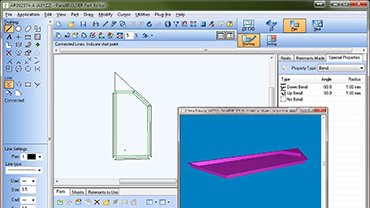

What is PANELBUILDER?

Is it a machine? Is it software? Actually, it’s both. Recognized as a highly sophisticated all-in-one solution, it combines easy-to-use software with a custom machine design. This makes it possible to process all types of cladding materials faster, more consistently and at a lower cost than ever before. One of its most unique features is the ability to customize machine process areas to suit all standard material sheet sizes. From 60″ (1.5m) x 120″ (3m) to a massive 85″ (2m) x 478″ (12m) or even longer in increments of 24″ (600mm), multiple sheet sizes can be processed at one time.

Software Like No Other

The AXYZ PANELBUILDER comes with exclusive software developed specially to meet the needs of panel fabricators worldwide. If you’re an existing CAD user, you’ll appreciate the easy integration with your CAD system for flexible nesting, automation and machine programming functionality. If you’re working on large projects, the PANELBUILDER’s ability to create panels automatically from spreadsheet data will prove to be a huge timesaver. Hundreds of panels can be created in seconds simply by importing data on a spreadsheet. This includes information about the panel type, dimensions, material, grain direction requirements and more.

Help Save the Planet

Industry leaders are always looking for ways to cut down on costs, mitigate waste and ultimately, reduce their carbon imprint. This is where the AXYZ PANELBUILDER outshines the competition. Its ability to improve production efficiency is enhanced through eco-friendly initiatives, like:

- Maintaining a library of standard material types and sizes, which are automatically updated globally as well as on a project basis. This ensures you always have the right types and quantities of material available at all times.

- Automatically storing leftover sheet remnants which can then be used on subsequent jobs, whenever possible.

- Automatically cutting extra copies of commonly used parts in any leftover areas of a sheet, as a way to provide useful ‘filler parts.”

But don’t take our word for it. Select the link below to read how one company successfully used the PANELBuilder to tap into a different business market.

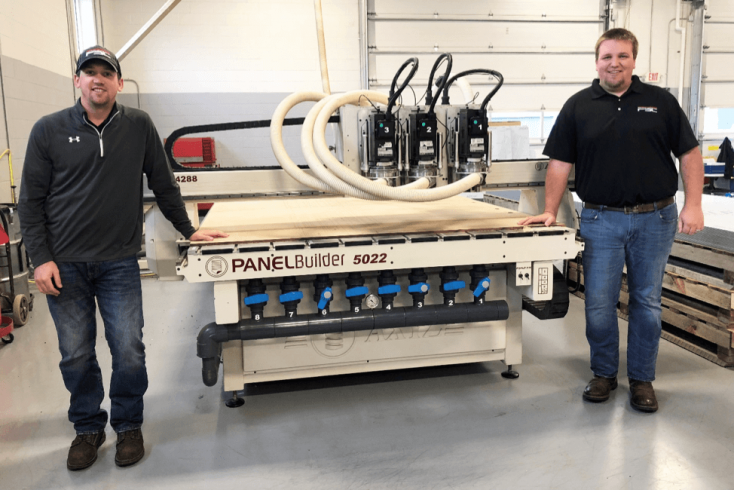

A Customer’s Success Story: PANELBuilder Helps Lewistown Company Grow

For Lewistown-based Penn State Construction, purchasing a PANELBuilder was the logical next step to help expand their business from commercial construction and renovation, to becoming the area’s only ACM panel provider. According to Jay Miller, VP of this family-owned business, “The PANELBuilder machine was built exactly for what we wanted to use it for.”

Videos

Watch the PANELBuilder in action in this video.

For More Information

For questions about the PANELBuilder, contact a member of your local Customer Care Team or fill out our online contact form.

For PANELBuilder accessories and options, visit CNCshop.com and check out our latest promotion.