Benefits of the Automated Label Printer (ALP)

Manually identifying your ACM panels with a marker wastes time. The same goes with applying pre-printed labels on individual parts by hand. You also run the risk of putting misinformation on the panels, which may impact your bottom line. A more efficient method is to use the AXYZ Automated Label Printer (ALP) – an optional device which can be fully integrated with your PANELBuilder machine. You can print labels before or after cutting the panel, which can be applied directly on individual panels. This saves time, reduces inaccuracies due to human error, and lowers production costs.

Automated Label Printing: Part of the PANELBuilder Solution

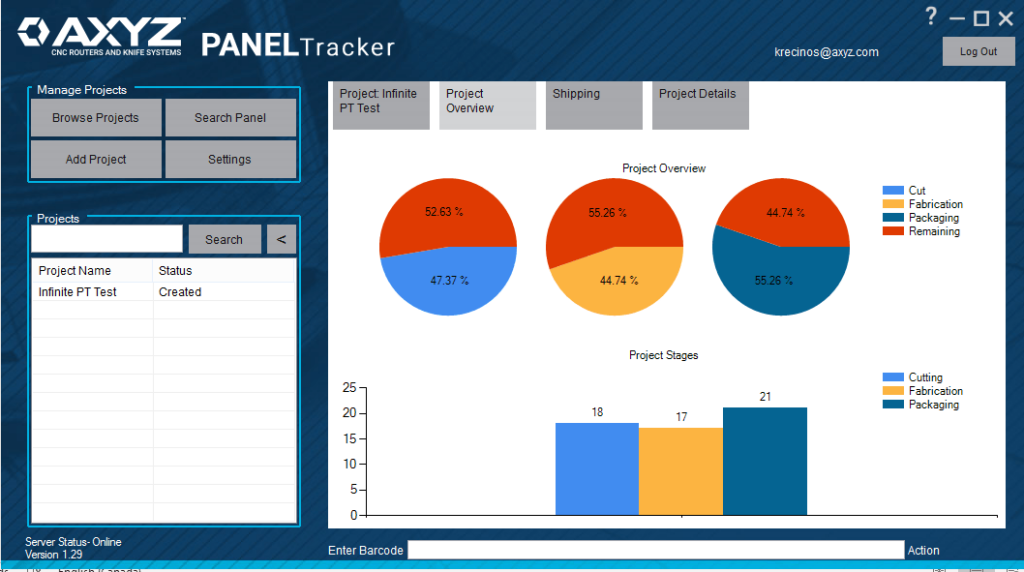

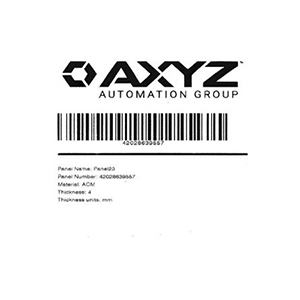

Combined with 1) the PANELBuilder CNC machine, 2) the PANELBuilder software and 3) the PANELTracker system, ALP plays an integral part in the process. Once the panel is designed and cut using the PANELBuilder software, ALP prints the data from the software, which may include a part name, unique bar code or company logo. Every process after that is easily captured using specific bar codes that come with your software package. Once the panel is fabricated, a bar code is scanned first and the printed label scanned second. This information is now updated as “fabricated” in the PANELTracker system. The same process is performed when the panel is packaged and shipped. If a panel is damaged, an email is sent to the Project Manager. This provides information about the damaged panel, as well as where the damaged occurred in the process. From design to cut and labeling to tracking, the AXYZ PANELBuilder bundle encompasses a very effective, all-in-one solution.

The Difference Between 1D and 2D Labels

ALP has the capacity to print different types of labels using permanent or semi-permanent adhesive strips. In addition to standard text, 1D or 2D matrix codes can be printed to provide different types of information. 1D refers to one-dimensional barcodes, the most common of the two. It reads data horizontally and usually limits data to 8-15 characters. When using 1D labels, the data usually includes basic information, like a product number, manufacturer name, address, etc. 2D or two-dimensional barcodes encodes data across two directions. They can include images, website addresses, audio and any type of binary information, up to 2000 characters. Also called QR codes, 2D labels are easily recognizable with their use of squares, dots, and hexagon patterns.

Data Capture with Bar Code Readers

If you’re printing 1D or 2D bar code labels, you’ll need a barcode reader to accurately capture the data. A multitude of options exist that can perform this function. From pen wands to image scanners to CCD scanners, all bar code readers send captured data to a specific computer software program to accurately translate the data. The most common type of bar code reader is the CCD (Charge Coupled Device) scanner, used predominantly in retail stores for price scanning. When pointed a few inches away from the bar code, this “gun” type interface scans data very quickly and accurately. For panel identification, this is ideal as it is the most convenient and economical bar code reader on the market today.

NEED MORE INFORMATION?

Fill out this handy online contact form with your specific requirements. If you wish to speak to one of our Sales Reps, contact your Local Customer Support Team.