The AXYZ Infinite is the most versatile CNC router in the industry. Configured to meet your application requirements, this advanced CNC machine can process virtually any material. Designed and manufactured in Ontario, Canada for over 30 years, the machine can perform some of the most advanced manufacturing processes, making it ideal for processing non-ferrous metals, composites, woods, plastics, and more.

Built to Your Specification

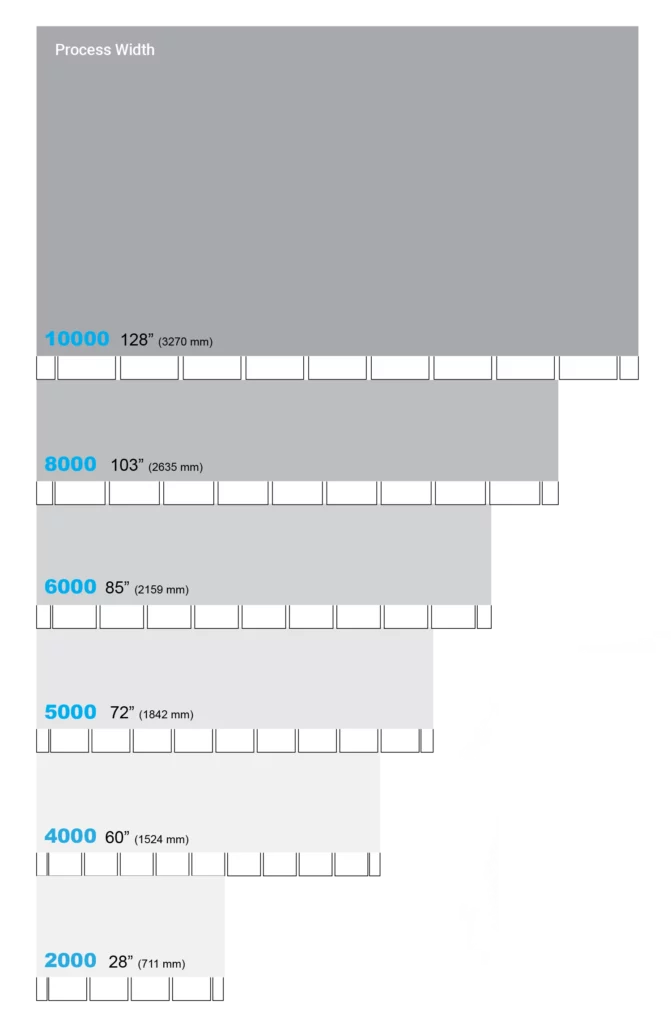

The Infinite is our modular and scalable platform with hundreds of thousands of combinations and permutations. We are proud of the engineered design that allows for this capability. The Infinite 4010 is our most popular size, representing a 5ft by 10ft (1.5m by 3m) process area. We manufacture machines of all sizes, from small to large, that accommodate a wide range of materials and thicknesses. Some examples of our powerful platform include our large-format configurations. For the marine and boat building industry, a common size is 16ft (4.9m) long by 6ft (1.8m) wide, configured with a 10-horsepower spindle, a pneumatic oscillating knife, a tool changer, and pop-up locating pins for accurate material alignment. Fitted with an optional dust collector and a minimum quantity lubrication (MQL) system used when cutting non-ferrous metals, the machine can process anything from furniture in the boat’s cabin to EVA foam used on the floorboard or large aluminum plates used for the hull.

Need to double your production? The same 16ft (4.9m) long machine can be configured in a 32ft (9.8m) size, offering double the performance. Infinite’s vast configurability makes it suitable for any CNC router application!

Pushing the Limits on Size

Our smallest size, the 2000 series, has a processing width of 28in (710mm), making it perfect for applications where loading happens on one side of the machine and unloading on the other—especially in automotive-style production environments where material needs to be constantly processed. Applications like aluminum extrusion fabrication for the glazing market benefit from a more compact machine that processes long, thin strips of material. Interested in an automatic tool changer or a high-horsepower spindle? The Infinite, even in its smallest form, can be fully equipped with these options and more, providing you with the power to process any job.

Efficient Workflow and Advanced Controls

The Infinite’s workflow is streamlined and efficient thanks to the A2MC controller and the optional AAG MOVE Control Interface. Your shop should be using automatic production job reports, which you can integrate further by adding a barcode to your job sheets. With the optional barcode reader connected to your machine, simply scan the barcode to load the next job, eliminating the need to constantly search for the correct file.

Unmatched Reliability and Performance

Reliability of equipment and its performance are paramount to the efficiency of any operation. The Infinite incorporates advanced, purpose-built design components that ensure machine longevity. This starts with a fully welded, tubular, high-strength structural steel base frame. A solid frame minimizes vibrations, allowing for the highest cut quality possible. Our aluminum t-slot deck is engineered by meticulously connecting and interlocking multiple metal plates, resulting in a structure that is both exceptionally sound and rigid. This advanced design ensures unparalleled durability and stability, making it ideal for a wide range of applications. The helical rack and pinion design allows for longer machine lengths while maintaining high accuracy, and its design offers quieter machine motion due to more surface area being in constant contact. Our linear rails are wire EDM cut to match the length of the machine, ensuring smooth and accurate machine travel.

Easy Serviceability and Future-Proof Upgrades

The serviceability of the machine is an important design consideration. AXYZ Engineering focused on ensuring access to key items such as filters, fuses, and pneumatics—even standardizing the size of screws to reduce the number of tools required for maintenance. Bearing grease points are positioned in easy-to-reach areas, and all electronic components are laid out in a simplistic yet organized fashion that allows for easy navigation and identification of components. The machine includes a set of tools needed to work on your machine. Smart maintenance (PM) can be executed by any trained operator with our easy-to-use instruction guide and 24-point maintenance reference.

The Infinite’s open-access design not only gives operators easy component-swapping capabilities but also allows for upgrades. As your business needs grow and applications evolve, so should your machine. Included are pre-defined built-in mounting locations that facilitate upgrades by providing space for other larger components and room for pneumatics and electrical cables that can be installed in the future. Are you looking for ways to keep a closer eye on your production and need a label printer? Give our aftermarket team a call! Consult with one of our team members to discuss the possibilities.

Possible Upgrade Options

| Upgrade Option | Description |

| Pressure Dust Foot | Various options available, including non-contact dust collection and pressure-based systems to hold parts down |

| Oscillating Knife | For flexible materials such as foams, rubbers, cardboard |

| Cold Air Gun | For dry cutting operations, reduces chip rewelding, and improves tool life |

| Label Printer | For labeling parts and tracking |

| Unist Mister | For non-ferrous metal cutting, reduces chip rewelding, and improves tool life |

| Tool Changer | Improves operational speed by introducing a tool changer or upgrading to a larger size; available in 7, 10, 14, and 21 positions |

Learn More About the AXYZ Infinite CNC Router

Thank you for reading our blog on the best CNC router in the market. To learn more about the AXYZ Infinite series and how it can transform your manufacturing process, watch our video or visit our website.