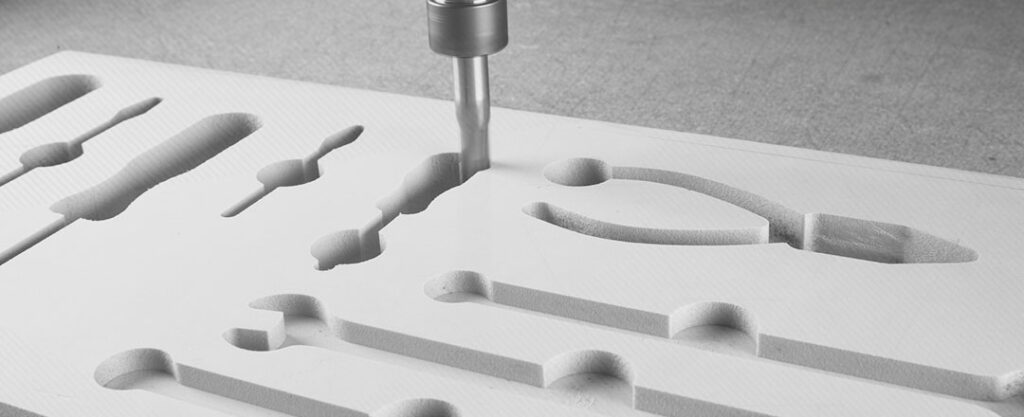

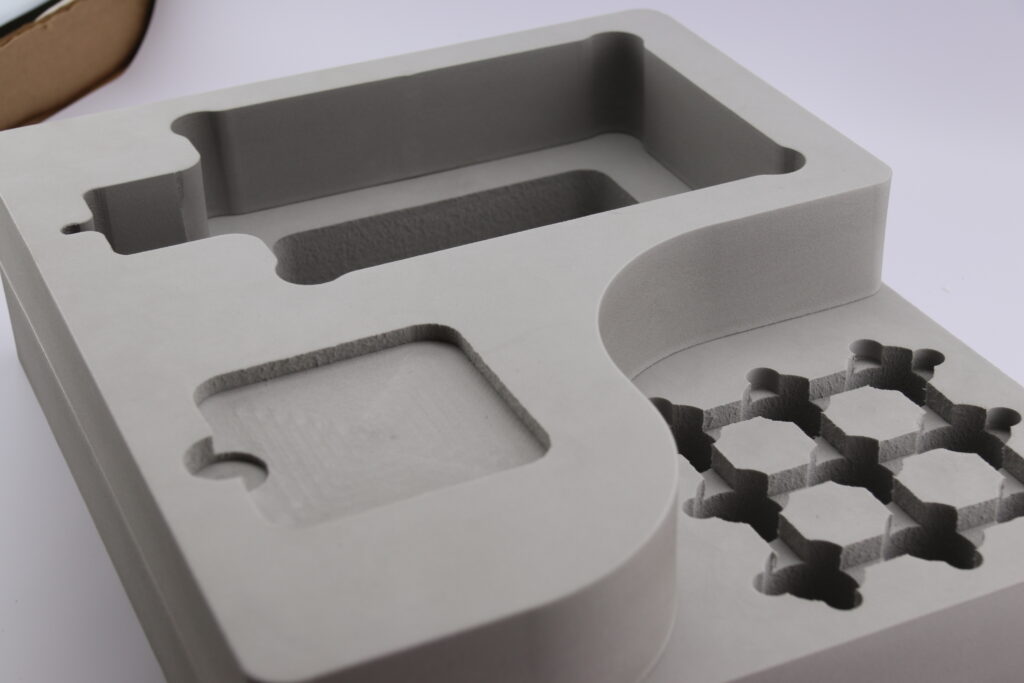

The advantage that a CNC router has over other cutting machines is the ability to cut “pockets” – a term that refers to a cut that does not go through the entire thickness of material. You’ll see pockets in either packaging, or intricate 2D/3D designs for the signs and graphics industry. Regardless of the application, pockets require specific tools and cutting methods that will give clean, smooth edge finishes every time.

Here are three tips to help you create superior pockets and 2D/3D designs:

1. Depending on the density of the material, use either a straight flute bit or high helix router bit to cut your pocket. The softer/lower density your material, the straighter your bit needs to be to ensure a clean cut with smooth edges.

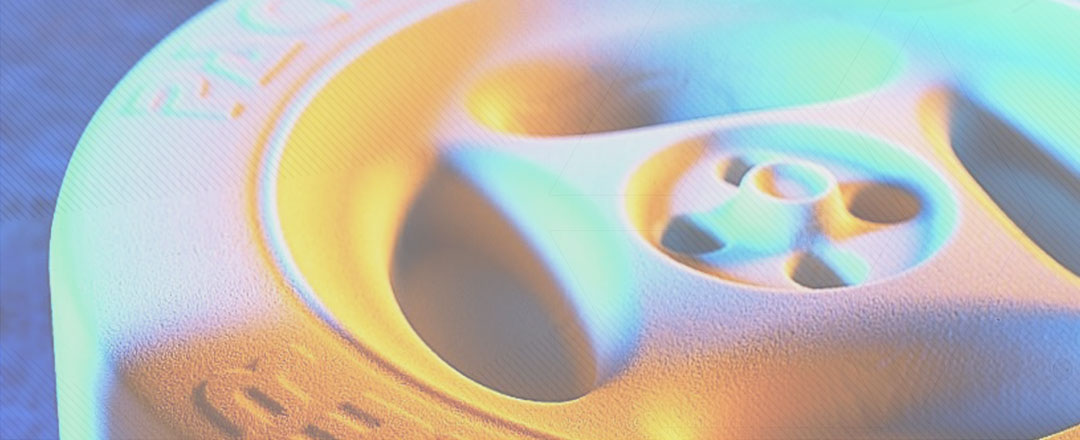

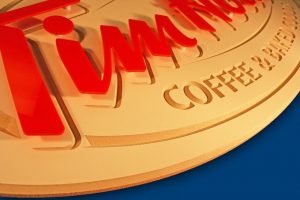

2. For 2D/3D designs, it’s usually better to use a ball nose bit as this will follow the contours better and leave less material for the finishing operation. Generally, the smaller the diameter, the more detail you will see.

3. When V-carving, use one v-bit to carve designs at different widths. By not changing bits halfway through a job, you’re going to save loads of time.

Watch the Trident CNC Router-Knife Hybrid in action.

The Trident combines different tooling methods to easily create pockets, 2D/3D designs and profile cutting all on the same machine.

Do you have specific questions about router bits and cutting strategies? Contact your Local Customer Care Team and discover which tool is best for your project.

To browse through our range of tools, options and accessories, visit CNCShop.com and take advantage of our latest promotion.