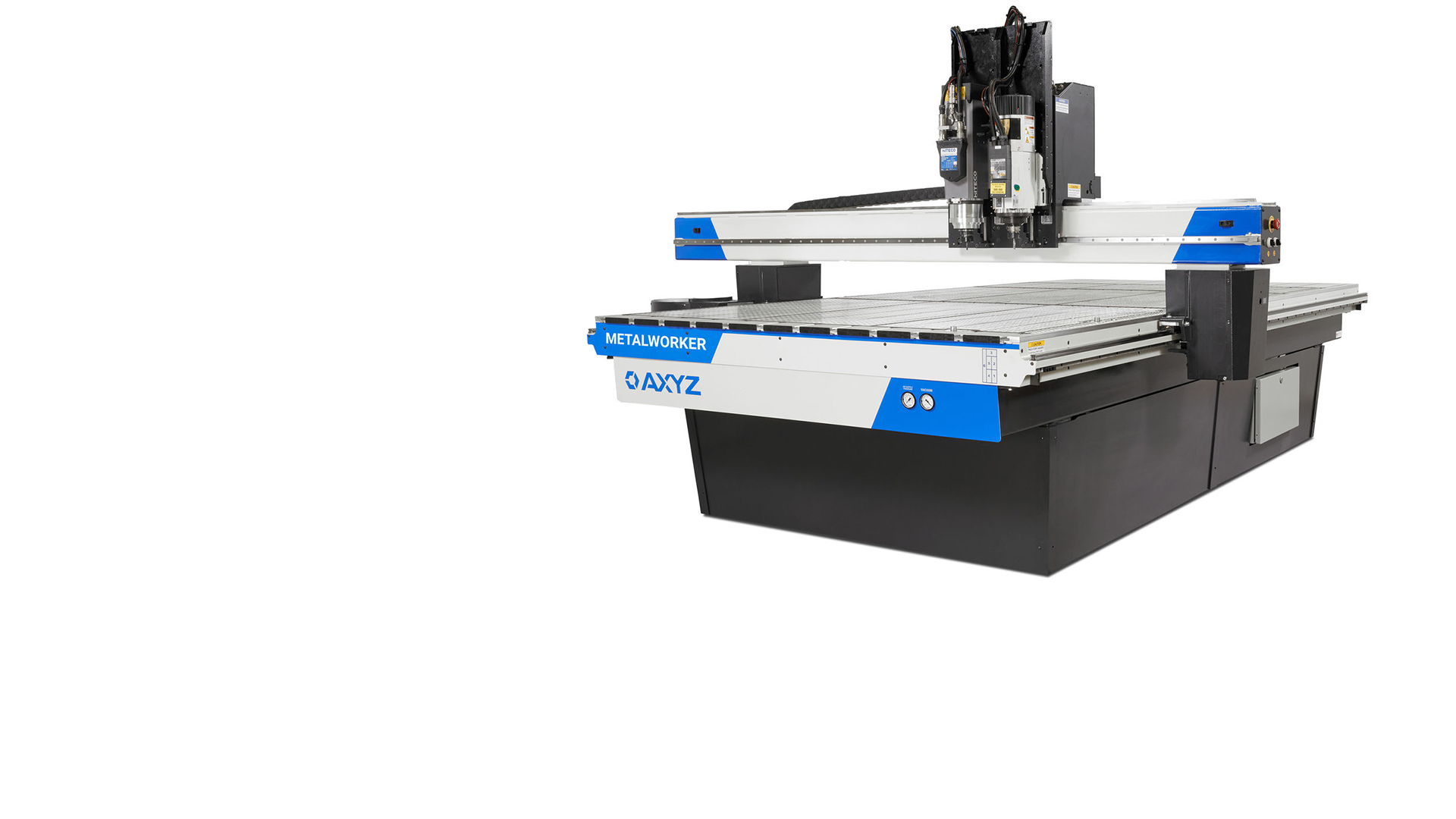

When shopping for a CNC router, it’s easy to think that price is the most important factor. While sticking to a budget is important, it is not the only consideration in the decision-making process. There may be some critical differences between the lower and higher priced CNC routers and, because of these differences, the lower-priced machines can end up costing more in the long run than the higher-priced models.