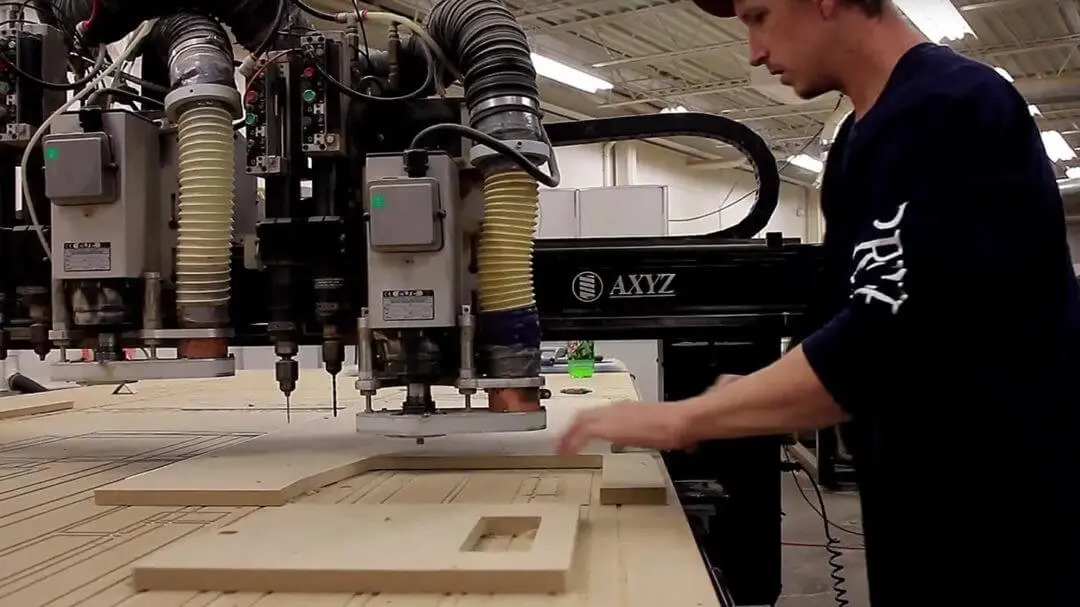

Precise CNC Routing Builds a Cutting Edge Business with AXYZ CNC Routers

Richard (Rick) Lemson started his company, Precise CNC Routing, in 1995 with the idea of offering a CNC routing service to a wide range of different industries. Based in Grand Rapids, MI the plan was simple – to build a business based upon providing the best quality of products and service at competitive rates. The decision on which machine to purchase was fairly simple. Rick had previously worked for a company where they had an AXYZ Router and he knew very well what it was capable of and how easy it was to operate. Rick said “I was well aware of how reliable the machine had been and the excellent service and backup that was provided by AXYZ and so even after looking at a few alternatives I knew this was the right machine to start my business with”. His first router was an AXYZ 5012 Series machine with twin cutting heads designed for high productivity and with this Rick started to target any local business which he thought would benefit from their service. He soon realised that there were opportunities everywhere and before long they were supplying machined parts to woodworkers, signmakers, plastic fabricators, exhibition builders and many more.

In their first year the business went from strength to strength with more and more customers being attracted, mainly by word of mouth, and the reputation that Rick was quickly building for fast delivery and an ability to tackle such a wide variety of jobs involving a diverse range of materials.

Despite having a machine that could cut two parts at the same time and Rick and his two sons who had also joined the business working long hours, they were in a position just over a year after starting where the business was running at full capacity. To avoid turning work away they needed to invest in a second machine. This time a larger AXYZ 5018 Series machine was purchased and with this addition the business was able to grow to such an extent that they needed to add two more machines within the next three years.

All of these new machines were the 5018 Series configured with twin heads and an additional pneumatic drill. The process area on the 5018 is 70” x 216” which was perfect for their needs. Much of the material being cut came in standard sheet lengths of 8 or 9 feet and this can be cut in a single operation. Also, as Rick explained “the other reason for a larger process area is that it allows a standard 4’ x 8’ sheet to be loaded on the front half of the table with another one on the back half. After the front sheet has been machined the router will continue processing the sheet on the back half, allowing the operator to change out the front sheet without any pausing of the machine. It’s features like this which allow us to achieve such high levels of productivity”.

Over the years, Rick has always looked for opportunities to add other complimentary services to his routing facility which allow him to offer a wider range of products and solutions. One such example was the introduction of a powder coating line for MDF wood products so now his woodworking customers can benefit from a ‘one stop shop’ for both routing and also powder coating. This forward thinking approach has helped Rick to grow his business into an operation which now occupies a 66,000 sq ft building – a far cry from the 24ft x 40ft barn where they started – and provides not just a CNC Routing service but also powder coating, plastic fabrication, print graphics and display services.

Another reason that Rick keeps on buying AXYZ machines is the way that they listen to his feedback and often take on board his suggestions for product development and improvement. One such example of this was Rick’s suggestion of a ‘repeat cycle’ function on the controller. Even with the continuous cycling of front / back machining it was still necessary to press the start button after each cycle which sometimes caused delays in productivity. Now, with this new feature, they can preset the number of cycles to repeat for truly uninterrupted operation. Rick said “many machine suppliers say they listen to customer feedback but often its only lip-service. In my experience, AXYZ really do listen and they really do act on it if they feel it is a valid and worthwhile suggestion for product improvement”.

As of 2010, Precise CNC Routing own 6 AXYZ Routers and are using them for cutting materials ranging from 3” thick clear acrylic to 1” aluminium and 2” MDF. A memorable one-off job was the remaking of a set of interior panels for a 1932 Hearse. There were obviously no drawings available so they had to use the original, rotted panels as templates and painstakingly recreate the correct contours in CAD for an accurate machined reproduction.

Rick is pleased with what he has achieved and with the help he has had from AXYZ over the years and is looking forward to more growth in the future. He commented “AXYZ made our business what it is today, literally! They have the best machine in that price range”

Get in touch

Product Brochures

Get a copy of AXYZ’s latest product brochure. Learn all about our extensive range of AXYZ CNC Routers. Choose between our six major brands – INFINITE, INNOVATOR, METALWORKER, TRIDENT, WOODWORKER and PANELBUILDER.