Case Study: AK Rubber & Industrial Supplies Ltd Increases Efficiency and Capacity with AXYZ CNC Routers

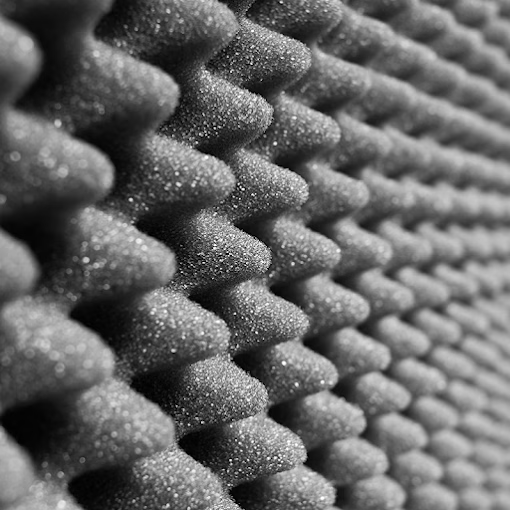

Located conveniently near the M11 between London and Cambridge, AK Rubber & Industrial Supplies Ltd has built a reputation over the years as a trusted manufacturer and supplier of high-quality, non-metallic products. Their extensive product line includes rubber sheeting, strip, matting, extrusions, moldings, gaskets and washers. With a commitment to bespoke manufacturing and quick turnarounds, AK Rubber supports a diverse client base across industries such as construction, structural steel and bespoke manufacturing.

As a company that thrives on delivering precision, flexibility, and speed, AK Rubber has continually looked for innovative ways to scale production while maintaining high standards of quality. The adoption of AXYZ CNC routers has been pivotal in achieving these goals.

AK Rubber began considering CNC router technology when its business in manufacturing thermal breaks started to rapidly expand. These essential components are widely used in the construction and structural steel sectors to prevent thermal bridging and AK Rubber’s growing list of clients required a scalable, repeatable production process.

“The decision to work with AXYZ was motivated by a clear need to support the growth of our business partners. We knew we needed to scale up, and fast. Given the positive experiences others in our network had with AXYZ machines, it was a logical choice” said Jack Fellowes-Prynne – Operations Manager.

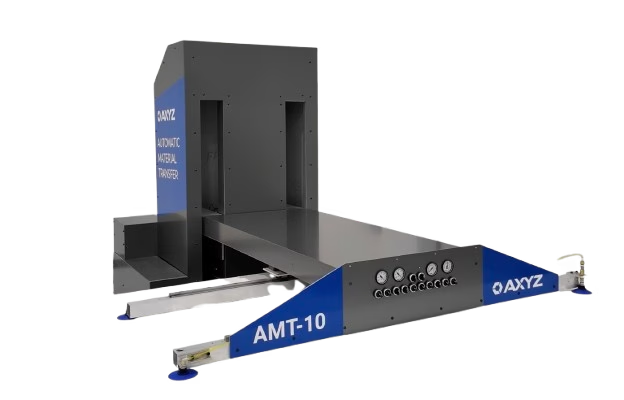

The company chose to invest in three Infinite series routers from AXYZ, a line known for its versatility, robustness and ability to handle a wide range of materials — from rubber and plastic to composites and foams. The INFINITE router is a highly configurable CNC machine that is suitable for one-off, small batch production as well as high volume and high productivity applications, including woodworking, plastic fabrication, engineered plastic machining and so much more. For a wide range of routing operations, one can choose from high-speed spindles ranging from 5HP to 15HP. For knife cutting, choose from a tangential knife, which can be used for creasing and folding applications or an oscillating knife which can be used to process soft goods material.

Although AK Rubber had years of experience with manual cutting processes and bespoke fabrication, adopting CNC router technology represented a significant shift in operations. As first-time users of automated routing systems, the learning curve could have been steep — but thanks to AXYZ’s customer support and training, the transition was smooth.

“AXYZ provided on-site training for both the machine and the drawing software that was key to helping our staff quickly build confidence in using the equipment effectively” said Jack Fellowes-Prynne.

This hands-on approach gave AK Rubber the ability to bring complex, custom cutting jobs in-house, improving speed and repeatability without compromising quality.

Today, AK Rubber operates three Infinite routers across their facility. The impact on production has been immediate and significant.

“We’ve seen a substantial increase in capacity,” the team explains. “The machines allow us to take on more work while reducing lead times across the board. It’s improved our efficiency and allowed us to serve clients faster and with even more precision.”

AXYZ routers now handle the bulk of cutting and shaping for thermal breaks, gaskets, washers and custom rubber components. Whether it’s a one-off prototype or a large production run, the machines offer the flexibility AK Rubber needs to keep up with demand.

“AXYZ provided on-site training for both the machine and the drawing software that was key to helping our staff quickly build confidence in using the equipment effectively” Jack Fellowes-Prynne, Operations Manager, AK Rubber

Beyond sheer productivity, the integration of AXYZ routers has brought deeper operational improvements:

Thanks to the automation and repeatability of CNC routing, jobs that once took hours now take minutes — without the need for manual rework.

The increased output has directly contributed to AK Rubber’s bottom line. “With higher production volumes, we’ve seen a rise in our workload, which in turn has boosted profitability.”

The adoption of CNC technology has changed the nature of work on the shop floor. “We’ve expanded our team to support machine operation and production, there have also been some role adjustments to reflect the new technology — overall, it’s been a positive development for our workforce” said Jack Fellowes-Prynne

Any piece of machinery is only as good as the maintenance behind it — and AK Rubber takes this seriously. Their AXYZ routers undergo monthly deep cleaning and lubrication to ensure continued performance and longevity.

By implementing a structured maintenance schedule, the company maximises uptime and minimises the risk of costly interruptions. “These machines are a major part of our production strategy, so keeping them in top shape is a priority.”

The adoption of AXYZ technology has given AK Rubber the confidence to look ahead with optimism. They are planning to invest in additional machinery in the future. “Our aim is to further enhance our capabilities and stay ahead of customer demand” explained Jack Fellowes-Prynne.

This proactive approach is typical of AK Rubber’s philosophy: embracing new tools that help them deliver better, faster and more competitively in a dynamic marketplace.

For AK Rubber, AXYZ has been more than a vendor — they’ve been a true partner in growth.

From the initial consultation to training, installation and post-sale support, AXYZ has played a central role in ensuring a successful technological transition. Their Infinite series routers continue to prove themselves daily on the factory floor, helping AK Rubber maintain their reputation for quality, reliability and responsiveness.

AK Rubber & Industrial Supplies Ltd is a company known for bespoke solutions, short lead times and outstanding customer service. By investing in AXYZ CNC routers, they have been able to maintain all these strengths — while scaling to meet rising demand.

Whether it’s crafting complex thermal breaks for the construction industry or manufacturing custom gaskets and washers for industrial clients, the team now has the tools, training and technology to meet every challenge head-on.

With a focus on continual improvement, AK Rubber is already looking to the future — and their AXYZ routers will be right there with them.

For more information on AK Rubber & Industrial Supplies Ltd

sa***@*********co.uk

Tel: 01279 719000

For more information on the AXYZ range of routers: www.axyz.com

Tel: 01952 291600

Get in touch

Product Brochures

Get a copy of AXYZ’s latest product brochure. Learn all about our extensive range of AXYZ CNC Routers. Choose between our six major brands – INFINITE, INNOVATOR, METALWORKER, TRIDENT, WOODWORKER and PANELBUILDER.