The Infinite Router excels at meeting the unique needs of different industries. From plastics, to rubber, to woodworking – its versatility allows for high precision cutting in a variety of applications. The Marine Industry in particular has achieved a high level of success with the Infinite’s multi-functional capacity. Whether it’s intricate designs for boat furniture or precision foam cutting, no job is too small or too big for the Infinite.

WHY BOAT BUILDERS CHOOSE THE INFINITE

The boat building industry has been increasing in popularity for many years, especially in the manufacturing of recreational boats. Due to the variety of sizes in sheet material, using a CNC router that’s appropriately sized, makes it easier to load and cut, all in one process.

Here are some other benefits:

- A Variety of Process Areas & Options – There’s no limit to the size of the material you can cut or available options to choose from. With process areas up to 128″ (3251mm) wide and over 50ft long (15.24m), there’s always a solution to suit your exact application requirements and budget. For cutting with high precision and accuracy, popular options include:

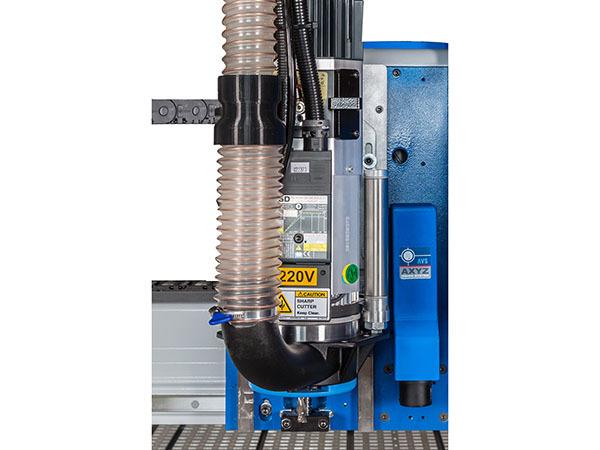

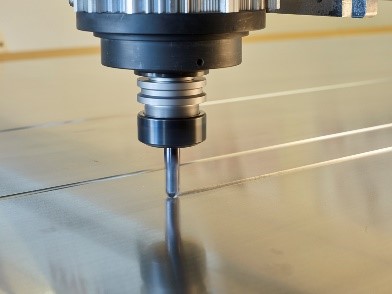

- High Speed Spindle – Increase boat building production and efficiency, and lower costs with a spindle from manufacturers like ELTE or HSD. Choose from a choice of manual, semi or fully automatic tool change and high-speed options for specialist applications.

- Automatic Tool Changer (ATC) – Minimize tool change time without any manual effort. This automatic tool changer carousel mounts on the gantry, containing, 7, 21 or even 33 tool stations.

- Oscillating Knife – The perfect tool for cutting flexible materials, like the variety of foam you’d use for boat cushions or seating. The sawing action of the oscillating knife allows it to slice through these materials with ease, delivering clean cut edges without fraying.

- Build to Last – With over 25 years of experience, we’ve developed a robust, heavy-duty machine boat builders can rely on. Its new design makes it easier for service, created from the redesigned welded carriage that ensures sturdiness and a sleeker aesthetic. A new dust extraction system reduces clogging and makes it easier to use longer tables.

High Speed Spindle

Automatic Tool Changer

Automatic Tool Changer

What Materials Can I Cut?

The Infinite cuts a diverse range of materials with high end finishes that boat companies have come to expect from an AXYZ machine. Some of these include:

- FOAM – EVA foam (Ethylene-Vinyl Acetate), Polyethylene (PE) or Polyurethane (PU) used primarily for boat floors or cushions.

- ALUMINUM/NON-FERROUS METALS – Specific types like aluminum plates (5052 grade) used in boat fixtures and structural parts.

- WOOD – Plywood and melamine used for cabinets and furniture.

PE/EVA Foam

Aluminum Fabrication

Wood

These are just a few examples; the Infinite has the capacity to do more. With so many elements to choose from, your boat will be as unique as the parts you’re cutting. With the Infinite, the possibilities are endless!

LOCAL SERVICE AND SUPPORT

For more information, call your local sales team. Enquire about various configurations, service packages or sign up for a remote viewing training session at a time that’s convenient for you.

For parts and accessories, visit CNCShop.com and check out our latest promotion.