Automate Your Cabinet Production from Raw Sheet to Labeled Parts

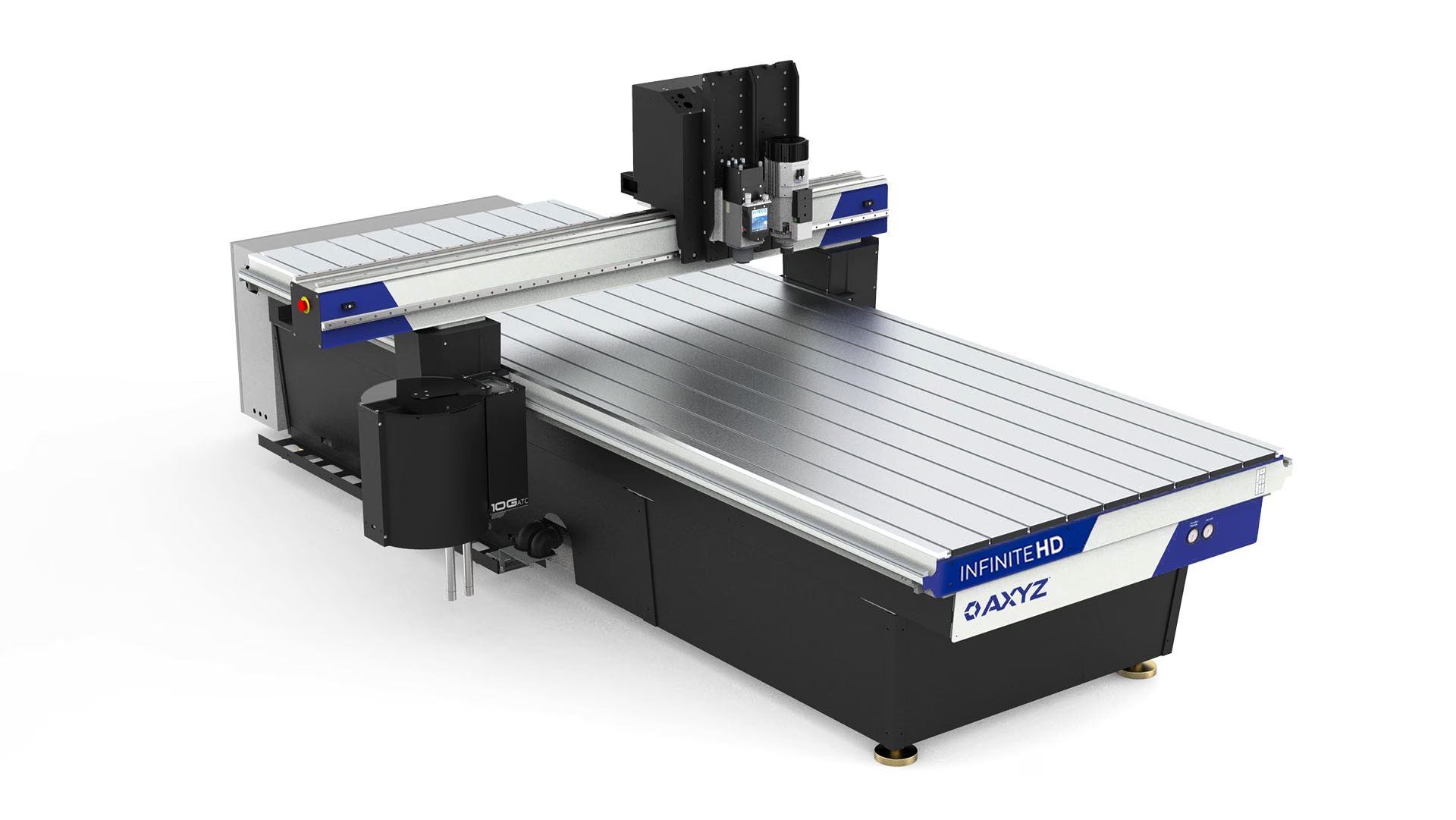

Cabinet shops are under pressure: tight deadlines, rising labor costs, and the need for flawless consistency. The LOADLINE Edge automated sheet loader and AXYZ WOODWORKER CNC router work together to eliminate bottlenecks and give you total control of cabinet production—from the first sheet to the final labeled part.

Stop outsourcing and start producing faster, cleaner, and more consistently than ever.

The Automated Cabinet Workflow

The system loads, cuts, drills, labels, and offloads your cabinet components in one smooth, uninterrupted sequence.

Advantage:

- Hands-free sheet loading

- Labels & barcodes for every cabinet part

- 9-position drill block for cabinet hole patterns

- Fast, accurate cabinet routing

- Automatic offloading and staging of the next sheet

- Continuous production with no operator waiting

Why Cabinet Shops Upgrade to Automation

✔ Achieve Perfect Repeatability

Door parts, stretchers, toe kicks, gables—every piece is cut and drilled exactly the same, every time.

✔ Faster Box Production

The 9-position drill block knocks out shelf pins and construction holes in seconds.

✔ Keep the Spindle Cutting

Load/unload automation eliminates downtime between panels.

✔ Meet Tight Install Dates

With predictable cycle times, your schedule becomes easier to manage—and easier to grow.

✔ Reduce Labor Strain

No more lifting heavy sheets or racing against manual bottlenecks.

Contact us to request a demo or customized automation assessment.