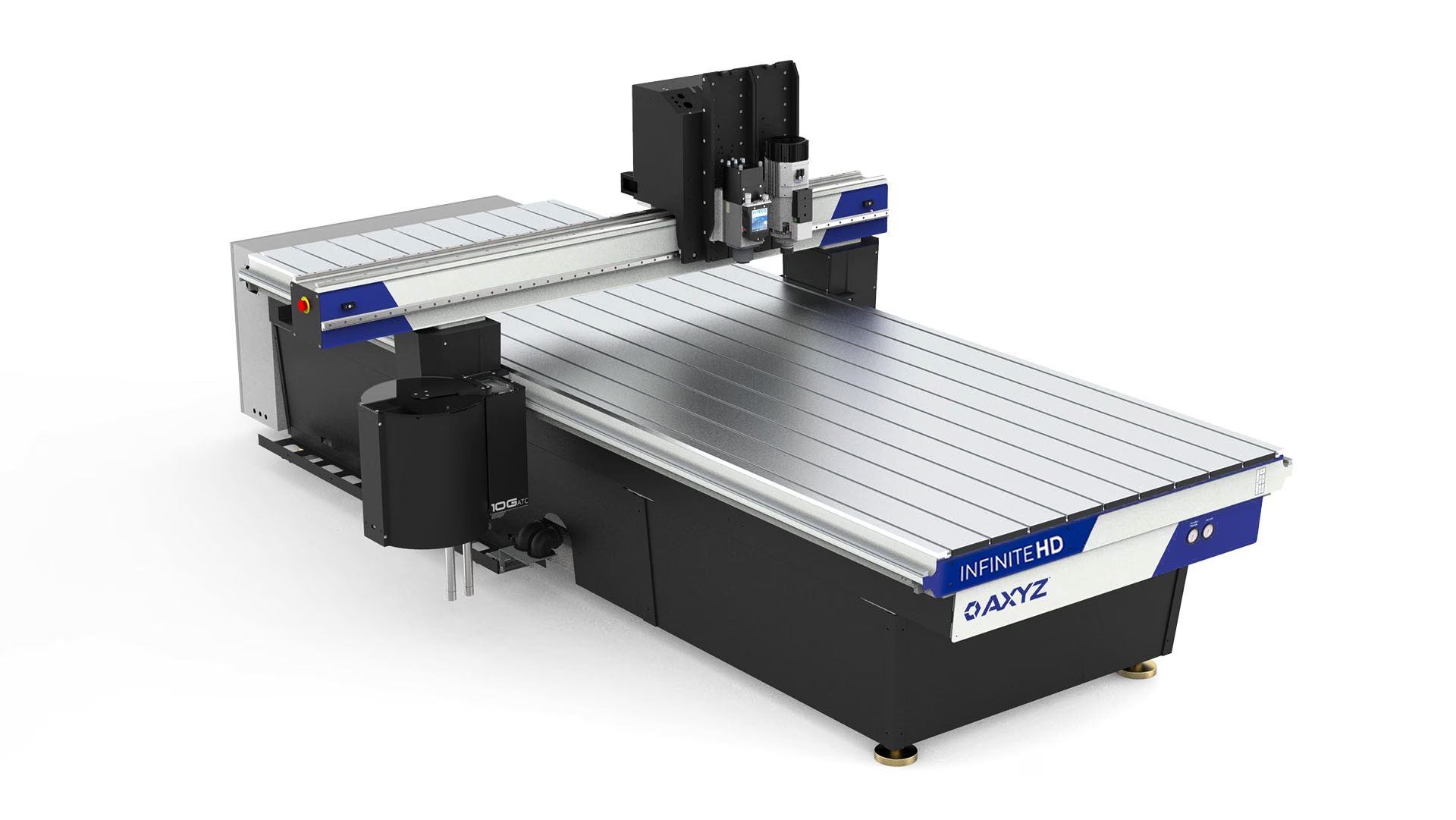

AXYZ LOADLINE HD Loading System

Transform your production workflow with fully automated sheet handling and CNC cutting.

The AXYZ LOADLINE HD, integrated with your CNC Router System, removes manual steps and delivers continuous, hands-free operation — ideal for high-volume fabrication environments.

It is engineered to lift up to 500 lbs (226 kg), handle full sheets up to 16 ft (4.87 m), and automatically align material using precision pop-up pins, creating a continuous, hands-free workflow for fast and efficient CNC routing.

Automation Built for Real Production Demands

The LOADLINE HD automatically loads, aligns, positions, and prepares sheets for cutting, turning a traditionally manual, labor-heavy process into a smarter, faster, and fully automated workflow.

Every sheet is precisely aligned before cutting begins — ensuring consistent accuracy, reducing waste, and eliminating the potential for human error.

Key Benefits

Shorter Lead Times

Automated sheet handling dramatically reduces downtime between jobs — keeping your CNC router cutting continuously and delivering projects faster.

Safer, Single-Operator Workflow

No more heavy lifting or dangerous material handling. The system is designed for safe, ergonomic operation with only one operator required.

Consistent Accuracy on Every Sheet

Automatic alignment technology guarantees uniform positioning, improving cut precision and reducing rework.

Reduced Manual Handling

Less labor and fewer touchpoints means fewer mistakes, lower operating costs, and smoother production flow.

Maximized Throughput

Seamless sheet loading + immediate CNC cutting = rapid, continuous production with higher output potential.

How the Integrated System Works

1. Automatic Sheet Loading

The LOADLINE HD lifts sheets directly from a stack and places them on the CNC router bed — eliminating manual material handling.

2. Precision Alignment

Sheets are automatically squared and positioned, ensuring perfect alignment for every cut.

3. Continuous Cutting Workflow

Once aligned, your CNC router begins cutting immediately, keeping production moving with no idle time.

4. Instantly Ready for the Next Sheet

As soon as one sheet is complete, the next is already being prepared — enabling continuous, uninterrupted operation.

Why Choose AXYZ for Automated Material Handling?

- Fully compatible with most CNC router systems

- Engineered for demanding, high-volume sheet processing

- Proven reliability in manufacturing and fabrication environments

- Increased ROI through automation, precision, and labor efficiency

Ideal Applications

- ACM / ACP panels

- Aluminum and composite fabrication

- Plastic and engineered materials

- Signage & cladding

- Repetitive, large-format sheet processing

- High-throughput production environments

Start Automating Your Production Today

If your facility needs higher throughput, safer handling, and superior accuracy, the AXYZ LOADLINE HD + CNC Router System delivers a fully automated workflow from raw sheet to finished part — with fewer steps, less labor, and unmatched consistency.

Contact us to request a demo or customized automation assessment.

FAQs

1. What is the AXYZ LOADLINE HD automated loading system?

The AXYZ LOADLINE HD is an advanced automated sheet loading system that integrates with most CNC router systems. It is engineered to lift up to 500 lbs (226 kg), handle full sheets up to 16 ft (4.87 m), and automatically align material using precision pop-up pins, creating a continuous, hands-free workflow for fast and efficient CNC routing.

2. Can the LOADLINE HD work with any CNC router system?

Yes. The LOADLINE HD is fully compatible with a wide range of CNC router systems. Whether you operate a single table or multi-shift production setup, the LOADLINE HD enhances throughput without requiring new CNC hardware.

3. How does loading full sheets improve CNC production efficiency?

Loading full-size sheets eliminates the need to manually cut down or handle oversized material before processing. The LOADLINE HD can lift heavy sheets up to 500 lbs and place them directly onto the router bed—reducing setup time, minimizing manual labor, and enabling continuous cutting cycles.

4. What material sizes can the LOADLINE HD handle?

The system is built for high-capacity sheet processing, supporting:

- Full sheets up to 16 ft (4.87 m)

- Material weights up to 500 lbs (226 kg)

This makes it ideal for large architectural panels, industrial plastics, and oversized composites.

5. How does the alignment system work?

The LOADLINE HD uses automated pop-up alignment pins to square every sheet accurately before cutting. This ensures consistent positioning, repeatable cuts, and reduced scrap—without requiring operator adjustment.

6. What materials can be loaded using the LOADLINE HD?

The system supports a broad range of sheet materials, including:

- ACM / ACP

- Aluminum sheets

- Plastics & composites

- PVC, HDPE

- Engineered materials

Its full-sheet capability also makes it suitable for cladding panels and large-format signage.

7. How many operators are needed?

Only one operator is required. Automated lifting, alignment, and placement remove the need for multiple staff to handle heavy or oversized sheets.

8. How does the LOADLINE HD improve worker safety?

The system eliminates manual lifting of heavy, full-size sheets, reducing risk of strain and injury. Operators stay safely clear of material movement, making production safer and more ergonomic.

9. Does full-sheet automation reduce labor and production costs?

Yes. Automated sheet loading and alignment reduce labor hours, minimize downtime between cuts, and ensure consistent accuracy—leading to fewer errors and lower cost per part.

10. What industries benefit most from the LOADLINE HD?

Industries processing large, heavy, or repetitive sheet materials see the greatest gains, including:

- Architectural cladding & façades

- Sign manufacturing

- Aluminum and composite fabrication

- Industrial manufacturing

- Large-format plastics processing

11. Does the LOADLINE HD increase cutting accuracy?

Absolutely. The pop-up alignment pins ensure every sheet is squared identically. This repeatability improves cut precision, reduces waste, and enhances overall production quality.

12. How does automated lifting improve workflow?

The ability to lift up to 500 lbs and load 16 ft sheets allows the CNC router to process full panels continuously—boosting throughput and enabling a true “load and cut” automated workflow.