Master the AXYZ Vision System with our top tips. Enhance your CNC machining accuracy and efficiency with expert guidance on using this advanced vision technology.

Archives: blogs

Achieve successful foam processing on your CNC router with AXYZ’s top tips. Discover best practices for cutting foam materials with precision and efficiency.

Most modern CNC routers allow simultaneous 3 axis control which means it is possible to cut quite complex and detailed 3D designs which are becoming increasingly popular for signmaking, moldmaking and many other applications.

Since the introduction of the A2MC controller back in 2008, we have worked tirelessly on innovation and ease of use for your machine operators. In conjunction with the SmartConsole, function codes are available to provide maximum flexibility for operators when at the machine.

This is the third installment in a four-part series on how to avoid bad cut edges when using CNC routers.

Since the introduction of the A2MC controller back in 2008, we have worked tirelessly on innovation and ease of use for your machine operators. In conjunction with the SmartConsole, function codes are available to provide maximum flexibility for operators when at the machine.

V Carving is a fast and easy way to create great looking signs and other products. Unlike full 3D machining V Carving is fast – it doesn’t require multiple passes and the results are very impressive. The simplicity of V carving is what makes it attractive. All you need to supply is a 2D design and the software will do the rest.

In the world of CNC there are so many options to choose and when it comes to tool selection it is no different. Tool selection is critical when it comes to achieving a desired surface finish, tool life, or cut speed of a specific material. Tooling manufacturers go to great lengths to engineer tools to deal with specific aspects and properties of certain materials. Selecting the right tool for the job could determine whether a job fails or succeeds.

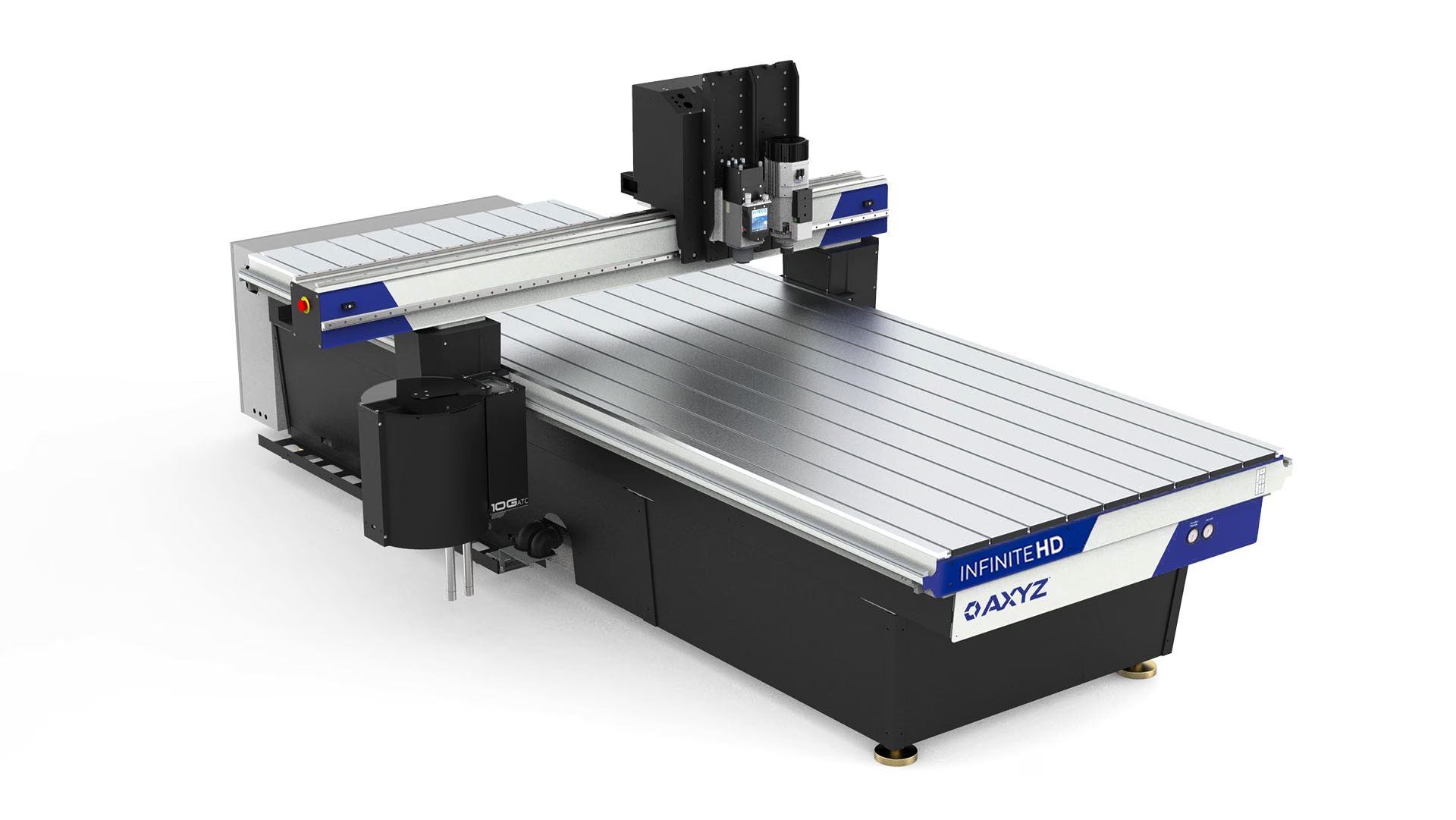

With over 368,058 standard machine configurations to choose from and multiple cutting options, we thought it may be useful to focus on the oscillating knife in more detail. Oscillating vs. Tangential At AXYZ we offer two knife units; tangential and oscillating. The tangential knife is the more robust of the two options, intended for processing […]

A nose rider is a popular option for AXYZ CNC routers. It is a relatively simple accessory which fits onto the bottom of the routing spindle and fixes its position relative to the pressure foot. The end result of this is to effectively ‘lock’ the height of the spindle to the surface of the material.