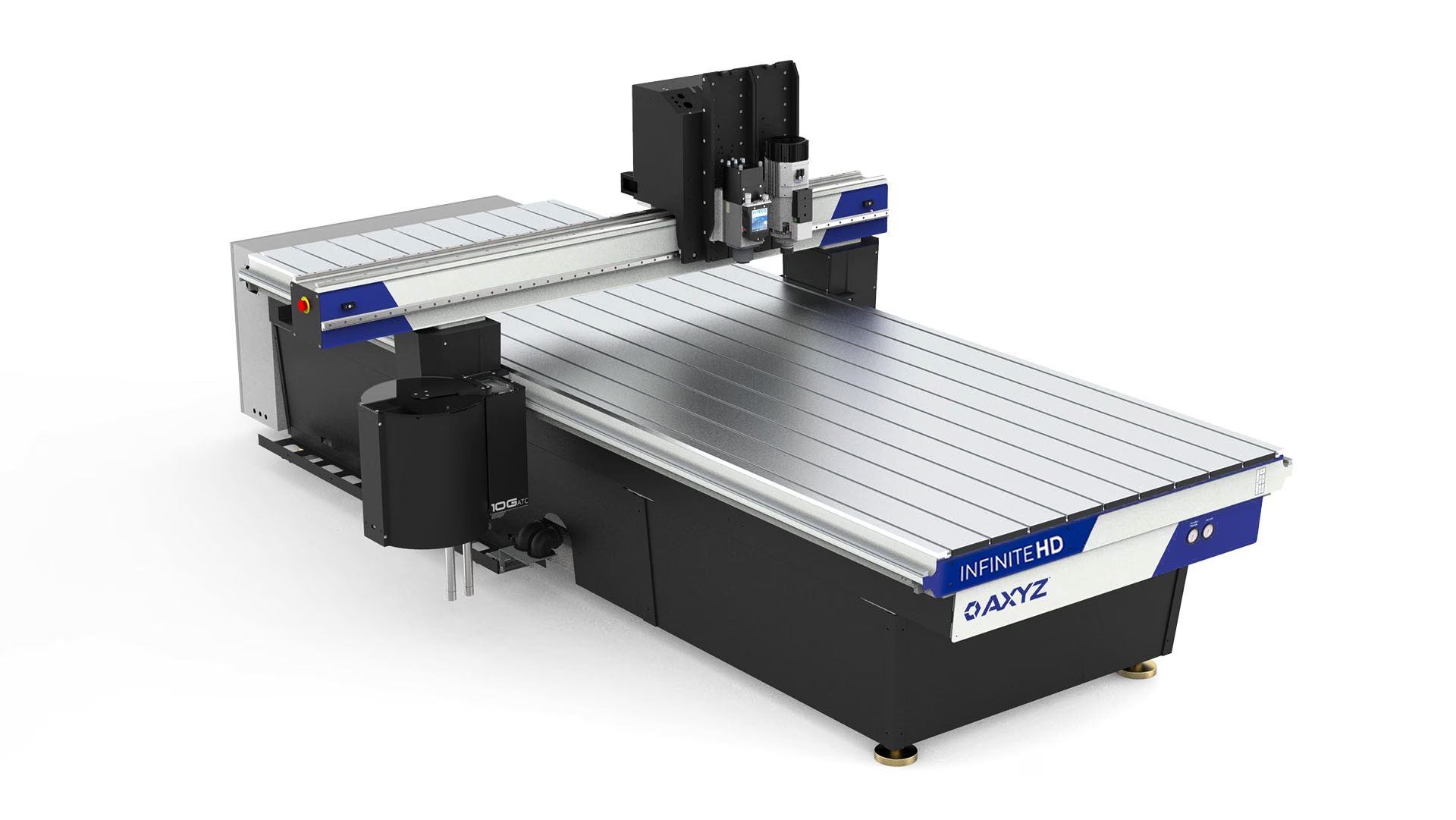

Simply stated, when it comes to CNC control technology, open architecture refers to a system that is not closed—one that can operate utilizing CAD-CAM programming that comes from a variety of sources. Also, it means assorted pieces of hardware (like a variety of tooling) can be used, depending on what type of materials need to be cut with a knife or router.