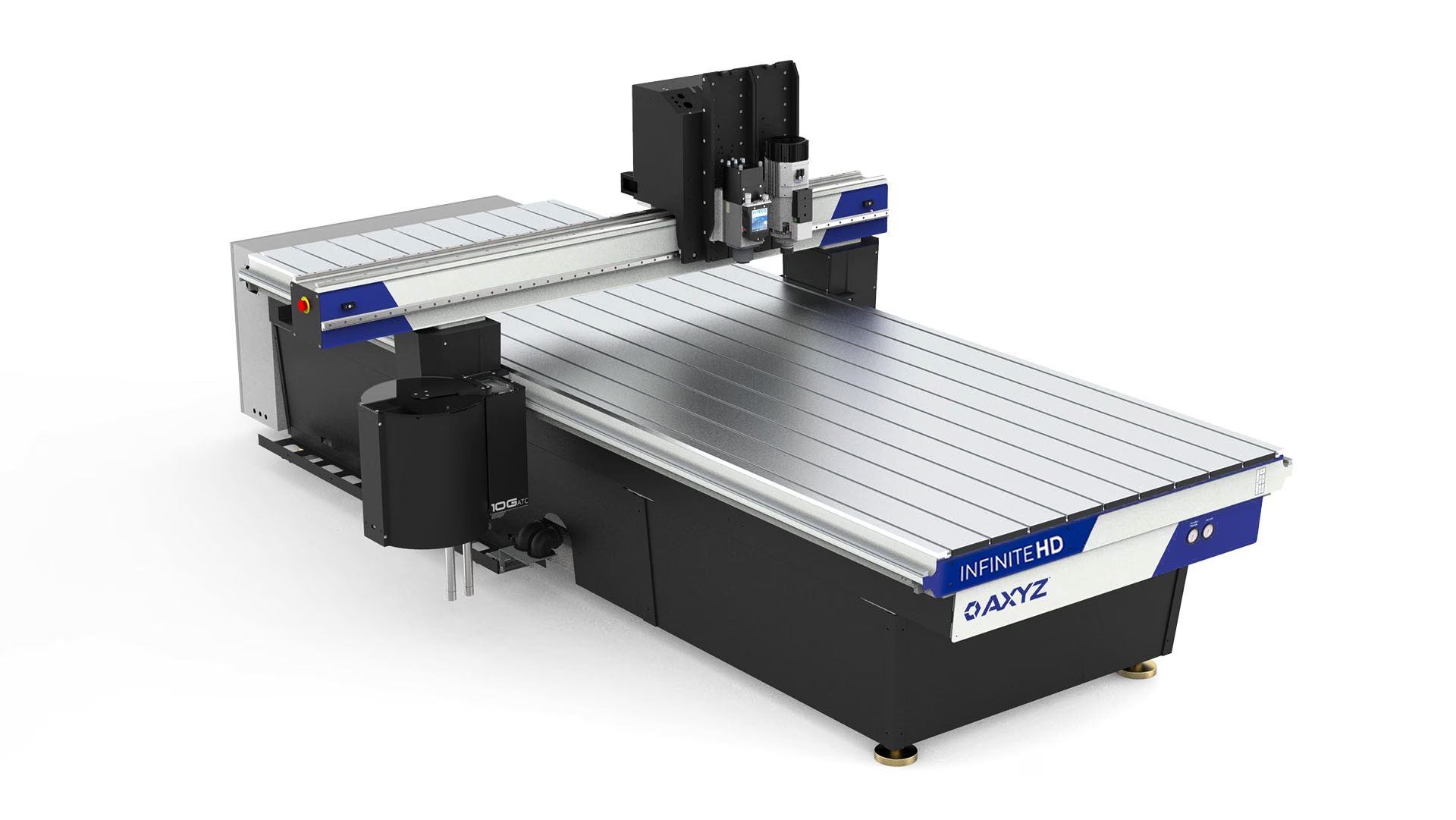

Engineered for Oriented Strand Board (OSB) Sheathing Production

Whether you’re processing 7/16” or 22/32” OSB sheets, AXYZ routers handle common sheathing sizes seamlessly.

- No vacuums. No clamps. No extra setup.

- Fast, consistent cuts designed for high-volume prefab operations

- Optimized motion control for clean edges and accurate panel dimensions

Designed for rugged, repeatable OSB cutting, AXYZ systems keep your line moving—job after job.

Roller Hold-Down System: Multiple Sheets, Zero Clamping

Forget pods, clamps, or time-consuming setups. The Roller Hold-Down system enables:

- Secure processing of multiple OSB sheets at once

- High-speed production without operator intervention

- Perfect for large workloads and batch-processing environments

Less handling. More output. Better efficiency from day one.

Cut Panels, Vent Holes & Outlets—All in One Pass

Eliminate secondary operations and re-handling. AXYZ routers automate the full sheathing workflow:

- Panel trimming

- Vent and service holes

- Electrical outlets

- Openings for windows, doors, and utilities

Everything is completed in one continuous operation, dramatically reducing overall cycle time and labor.

Smarter OSB Automation = More Output With Less Setup

Manual setups and mechanical workarounds slow your production floor. AXYZ routers are:

- Built for nonstop throughput

- Optimized for repeatability and accuracy

- Engineered for minimal operator adjustments

More cutting, less configuring. That’s smarter OSB automation—and it delivers measurable ROI for every shift.

Purpose-Built for Prefab Shops, Panel Builders & Wall Sheathing Lines

AXYZ CNC routers fit perfectly into modern off-site and modular building environments, including:

- Prefabrication facilities

- SIP and panel-building production

- Wall sheathing lines

- Modular and off-site construction workflows

- High-volume manufacturing environments seeking tighter QC

If your business demands consistent, scalable, repeatable cutting performance, AXYZ routers are built for you.

Why AXYZ for Construction?

- Proven reliability in industrial environments

- Customizable table sizes for oversized materials

- Fast turnaround and superior cut quality

- Automated efficiency for growing production needs

- Technology that reduces cost per panel and boosts total daily output

Contact us to request a demo or customized automation assessment.

Frequently Asked Questions (FAQs)

1. What sizes of OSB sheathing can AXYZ cut?

AXYZ routers are engineered to handle common OSB sheathing sizes—including 7/16” and 22/32”—with no special setup required. The system cuts full sheets accurately without vacuums, clamps, or pods.

2. How does the Roller Hold-Down system work?

The Roller Hold-Down system securely compresses and stabilizes one or multiple OSB sheets during cutting. This eliminates the need for pods or clamps and allows fast, continuous processing—perfect for high-volume panel production.

3. Can the router cut vent holes, outlets, and openings?

Absolutely. AXYZ routers can cut sheathing panels, vent holes, electrical outlets, windows, and utility openings all in one pass. This reduces secondary operations and improves production speed.

4. Do I need a vacuum table to process OSB panels?

No. AXYZ routers processing OSB sheathing do not require vacuum tables. The Roller Hold-Down system provides all the stability needed for accurate, repeatable cutting—even on stacked materials.

5. Is this system suitable for prefab and modular construction?

Yes. AXYZ routers are specifically built for:

- Prefab manufacturing

- Panel builders

- SIP shops

- Wall sheathing production lines

- Modular and off-site construction facilities

They are optimized for high throughput, consistent accuracy, and automated workflows.

6. Can the machine handle multiple sheets at once?

Yes. The Roller Hold-Down allows the router to process multiple OSB sheets simultaneously, increasing productivity and lowering labor cost per panel.

7. How fast is the setup process?

Setup is extremely fast. No clamps, pods, or vacuum prep means operators can load materials and start cutting right away. This “Less setup, more output” approach is a key advantage of AXYZ automation.

8. What types of materials besides OSB can the router cut?

AXYZ routers can process a wide range of construction and building materials, including:

- Plywood

- MDF

- SIP skins

- Foam cores

- Composite panels

- Plastics and laminates

Versatility makes it a long-term asset for expanding production needs.

9. How does AXYZ ensure cutting accuracy for panel builders?

High-performance motion control, industrial-grade spindle options, and precision tooling ensure consistent accuracy across long production runs. This is critical for modular assemblies and tight-tolerance wall sheathing.

10. Is training available for operators?

Yes. AXYZ offers comprehensive training during installation, along with ongoing support, maintenance resources, and programming assistance to ensure your team is fully prepared.

11. Does this system integrate with design or CAD workflows?

Yes. AXYZ routers support standard CAD/CAM file formats, making it easy to import cut files for panels, openings, SIP layouts, and sheathing designs.

12. What makes AXYZ routers a smart investment for construction companies?

Companies choose AXYZ because the system provides:

- Higher throughput per shift

- Reduced labor dependency

- Lower error rates

- Minimal setup time

- Long-term reliability

This combination results in lower cost per panel and greater daily output, delivering clear ROI for production facilities.