Case Study: SL Plastics Strengthens Production Capabilities with AXYZ INFINITE CNC Technology

A 35-Year Manufacturing Partnership Driving Precision, Reliability and Growth

For more than three decades, SL Plastics has been a quietly influential force inside Britain’s machine-building supply chain. From their facility in the East of England, the company has become a trusted specialist in precision-machined parts, supplying engineered components into some of the most demanding industrial environments in the country — including food processing, packaging, conveyor and bottling machinery.

Today, the business supports machine builders with a true “one-stop-shop” model for machined parts, including guides, wear strips, change parts and guarding assemblies. Meeting the expectations of these industries requires a rare combination of tight tolerances, repeatability, reliability and throughput. For SL Plastics, achieving that standard consistently has depended heavily on the company’s strategic commitment to CNC routing technology — and in particular to a long-standing partnership with AXYZ.

A CNC Journey That Began in 1991

SL Plastics began machining sheet plastics in 1991, at a time when CNC routing was still emerging as an enabling technology for plastics manufacturing. Their very first CNC router came from Pacer Systems — a brand which would eventually become part of AXYZ, laying the foundation for a technical and commercial partnership that has now lasted 35 years.

From those early days, the company recognised that the machining demands of sheet plastics were uniquely challenging. Thick polymer stock materials and engineered plastics continue to be a staple in food and processing machinery due to their chemical resistance, lubrication-free operation and cleanability, but they can be difficult to machine without the correct rigidity, spindle power and vacuum hold-down performance. Over time, those challenges drove SL Plastics toward increasingly specialised CNC platforms.

“After 35 years the continued support and innovation from AXYZ has been a strong partnership. After 9 machines we have every confidence in AXYZ… we are unlikely to look elsewhere as we continue to expand year on year.” – SL Plastics

Why AXYZ — Machines Design Matched to Real Manufacturing Requirements

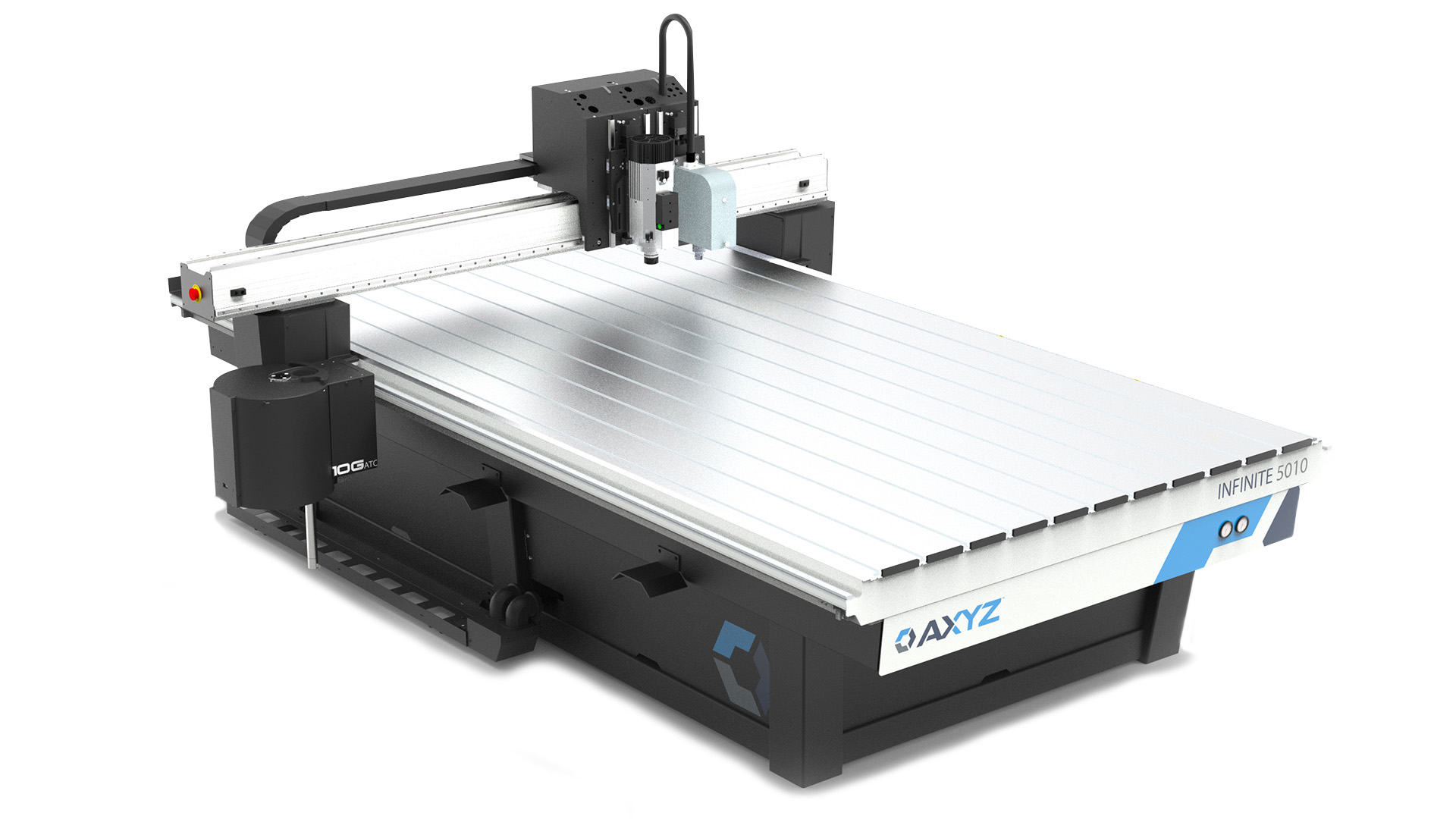

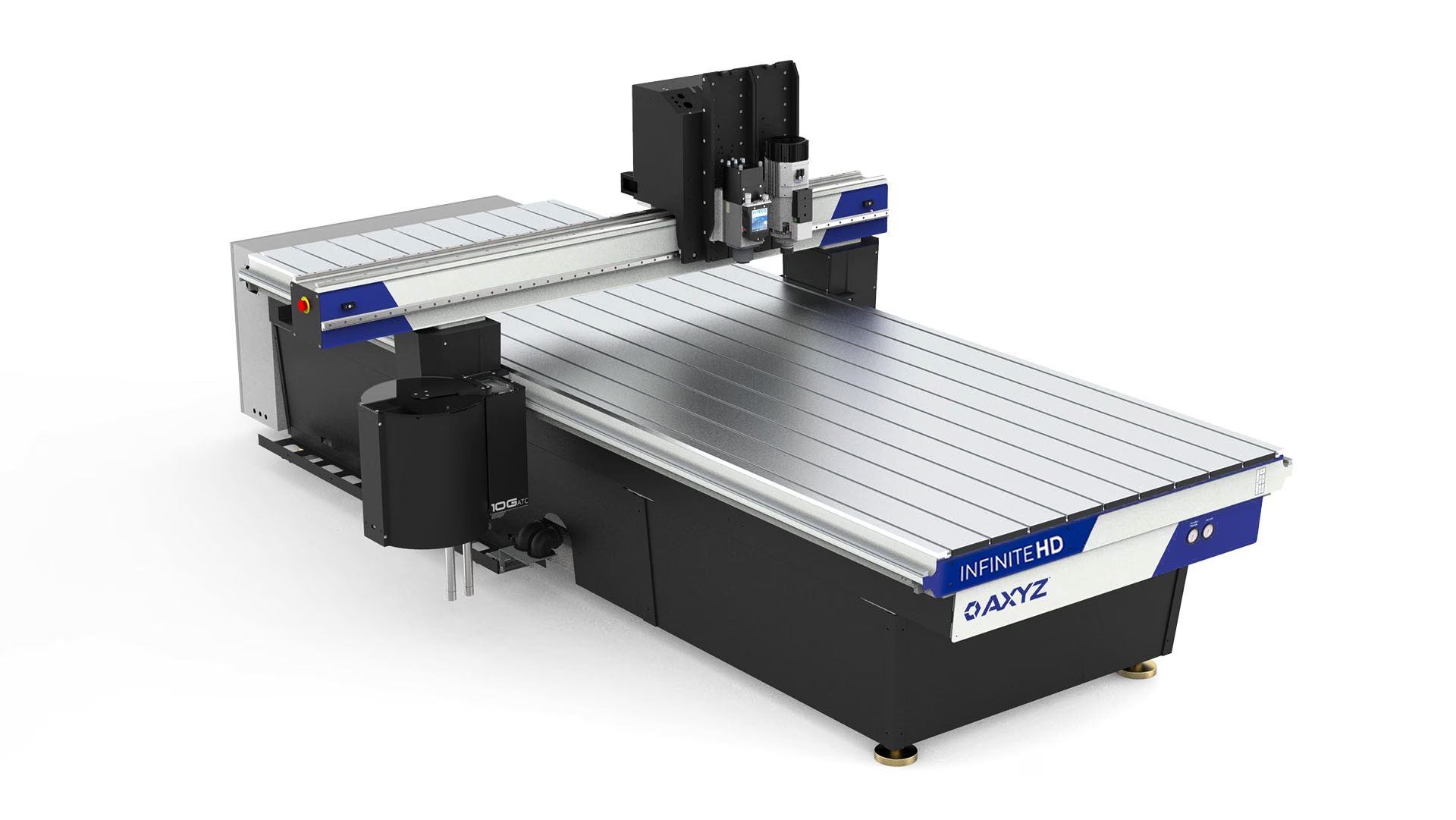

Over the years, SL Plastics has owned nine AXYZ CNC routers. The majority have been INFINITE series systems, including their latest acquisition: the INFINITE 6010. The decision to standardise around the INFINITE platform was shaped by a mix of technical, operational and commercial considerations.

Sheet Size Capability

The plastics used by SL Plastics are typically supplied in large formats, often up to 3m × 2m. Bed size therefore became a primary factor when selecting CNC platforms. As the company puts it:

“We have found these to be robust & reliable whilst also offering a bed size that suits the largest sheets we machine materials 3mtrs x 2mtrs”.

The INFINITE 6010 provides that footprint without compromise, allowing stock sheets to be processed with minimal trimming or waste. This also reduces manual handling and improves material logistics within the plant.

Power and Accuracy for Thick Plastics

High-density engineering plastics such as UHMW and acetal are widely used in conveyors, bottling machines and food-grade OEM equipment. These materials can be 50–100mm thick and require both torque and rigidity to machine efficiently. SL Plastics reports: “They have also proven themselves to have the power and accuracy for us to machine even the thickest sheets”. Cut quality and dimensional accuracy are non-negotiable since the majority of parts are functional machine components, not purely cosmetic.

Robustness and Reliability for Continuous Production

Unlike prototyping or small-run workshops, SL Plastics machines run daily on production tasks.

“Our portfolio of AXYZ machines ensure we remain very competitive… giving us also the reliability that is needed for machines that are being worked 8 hours a day every day.”

Continuous operation places unique demands on spindle longevity, vacuum systems and controller stability — areas where the company credits AXYZ with proven industrial robustness.

Introducing the INFINITE 6010 — SL Plastics’ Latest Investment

The company’s newest addition — the INFINITE 6010 — reflects the current generation of AXYZ innovation. The INFINITE platform is designed for large-format industrial routing with configurable options for multi-head operation, tool-change automation, enhanced vacuum, 24/7 production and peripheral automation technologies. The INFINITE router is a highly configurable CNC machine that is suitable for one-off, small batch production as well as high volume and high productivity applications, including woodworking, plastic fabrication, engineering plastic machining and so much more. For a wide range of routing operations, one can choose from high-speed spindles ranging from 5HP to 15HP. For knife cutting, choose from a tangential knife, which can be used for creasing and folding applications or an oscillating knife which can be used to process soft goods material.

For SL Plastics, performance of the INFINITE platform is closely tied to:

-handling of oversized sheet stock

-integrated vacuum zoning

-throughput efficiency

-repeatable accuracy

-high-duty spindle performance

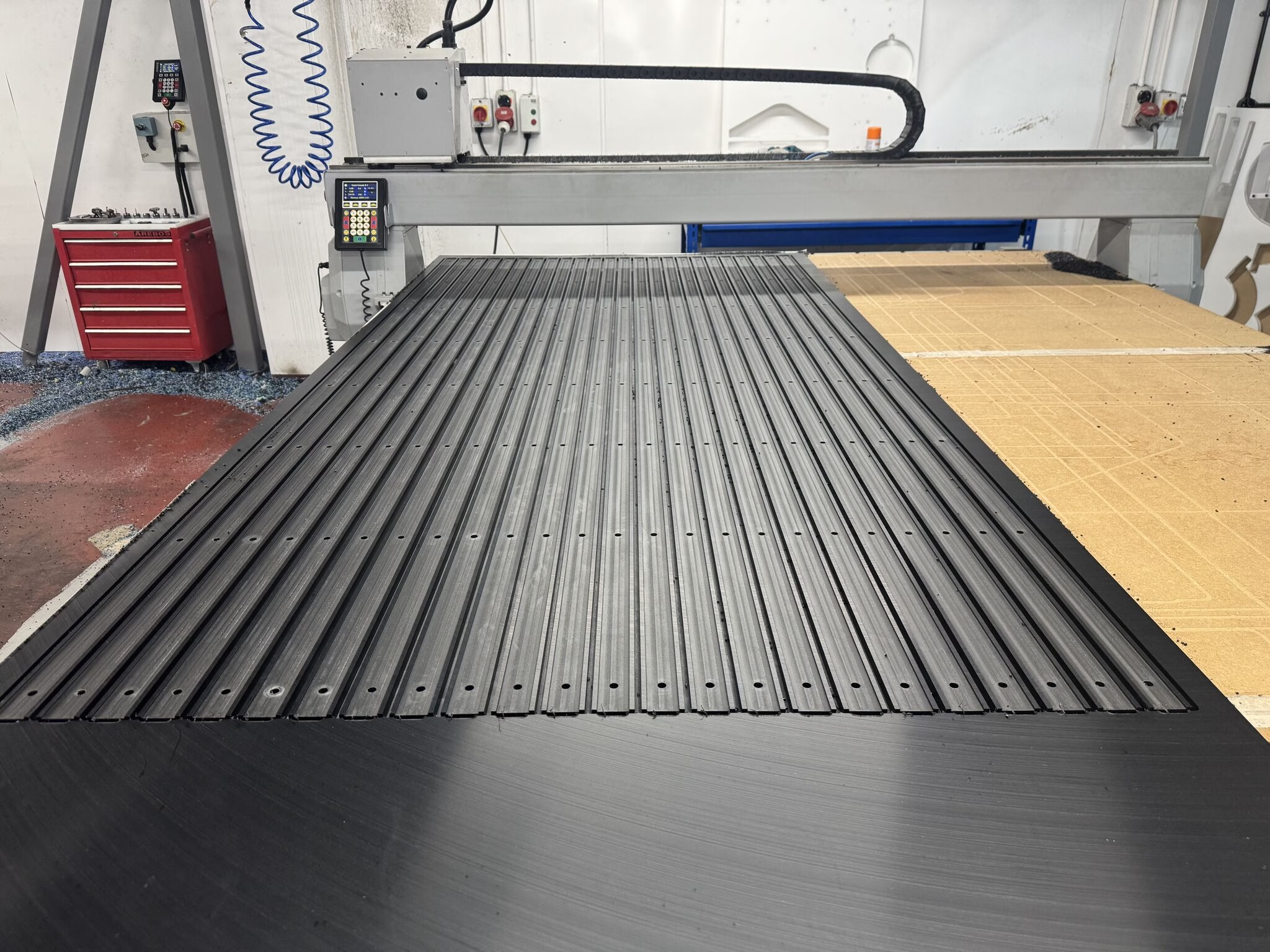

One feature highlighted by the company is the vacuum bed zoning system:

“The ability to select the bed area that is vacuumed allows us to use any size of sheet or off-cut ensuring we get maximum yield from all material.” Yield is a major cost driver in plastics manufacturing; optimising hold-down allows SL Plastics to extract value from offcuts that might otherwise be scrapped or downgraded.

Improving Efficiency, Automation and Output Quality

Over the past 35 years, CNC technology has transformed SL Plastics’ production workflows. The company points to three key operational benefits:

Consistency and Repeatability

Companies like SL Plastics expect interchangeable components with high dimensional consistency — particularly for wear strips, guiding parts and changeover assemblies. CNC routing ensures that a single digital file can produce repeatable results across batches or years.

“AXYZ machines provide consistency not only in performance but also accuracy… this is critical to our own performance and efficiency.”

Material Utilisation and Sheet Nesting

Large sheet capacity and vacuum zoning allow more aggressive nesting strategies, reducing waste and labour.

Faster Production Cycles and Reduced Manual Machining

Before CNC technology was adopted, many polymer parts were produced using manual routing, drilling or milling techniques — slower, more labour-intensive processes that relied heavily on operator skill.

CNC automation has allowed SL Plastics to redirect labour towards value-added tasks while maintaining shorter lead times for OEM customers.

Integration and Workforce Development

Notably, the company reports that transitioning staff onto AXYZ equipment requires minimal training:

“Using the machines requires minimal training so it’s very simple to transition members of staff from manual machining to using these CNC routers.”

This has had a positive workforce impact in two ways:

• reducing dependency on highly specialised manual machinists

• enabling career progression within the CNC machining team

In fact, the company notes:

“These machines have enabled us to effortlessly expand our CNC routing team and so give more opportunities to our staff for career progression.”

Reliability, Software and Support — The Other Half of the Equation

SL Plastics emphasises that the technology alone isn’t the full story; the partnership has endured because the aftercare and application support have been equally robust.

“After 35 years the continued support and innovation from AXYZ has been a strong partnership.”

Occasional Windows update conflicts are cited as the primary integration issue encountered over three decades — and AXYZ support remained proactive:

“AXYZ are always ahead of the game to resolve any software glitches if that happens.”

Maintenance is managed through a hybrid model:

• in-house scheduled maintenance routines

• annual service contract with AXYZ

This reduces unexpected downtime and protects spindle and vacuum system performance — critical for a machine that runs daily in a production environment.

Cost Competitiveness and Market Positioning

In markets such as food and packaging machinery, competition is intense and OEMs increasingly expect short lead times. SL Plastics views CNC investment as a strategic requirement for staying competitive:

“Our portfolio of AXYZ machines ensure we remain very competitive within the marketplace”.

CNC automation has protected the business from:

• rising labour costs

• increased material pricing

• OEM downtime penalties

• more demanding product tolerances

The machines are described as central to the company’s commercial longevity.

A Partnership Built for the Future

After nearly four decades and nine machines, the intent going forward is clear:

“After 9 machines we have every confidence in AXYZ… we are unlikely to look elsewhere as we continue to expand year on year.”

For an industry where switching suppliers can be costly and operationally disruptive, such loyalty is noteworthy. It reflects not just satisfaction with past performance but confidence that the platform will continue to support future capacity expansion and technological evolution.

Conclusion

SL Plastics’ journey highlights the role that CNC routing technology plays in enabling British manufacturers to compete in high-expectation industrial supply chains. The INFINITE 6010 platform now sits at the centre of a production strategy built on:

• large-format sheet capability

• robust industrial construction

• accurate and repeatable machining

• high-duty utilisation

• strong OEM support

For a business that has survived — and grown — across multiple decades of economic cycles, shifts in manufacturing models, material science changes and customer expectation escalation, its long-standing relationship with AXYZ stands as both a technical and strategic success story.

For more information on SL Plastics www.slplastics.co.uk

Tel: 01842 820400

Email: sales@slplastics.co.uk

For more information on the AXYZ range of routers:

www.axyz.com

Tel: 01952 291600

Entrer en contact

Joignez-vous à notre équipe

Votre emploi idéal n’est qu’à un clic. Jetez un œil à nos opportunités actuelles ici.