Reading time: ~ 3 minutes

What Are Structural Insulated Panels (SIPs)?

Oriented Strand Board (OSB)-faced Structural Insulated Panels (SIPs) are most common in residential and light commercial buildings, where they replace studs and sheathing to form load-bearing walls, roofs, and sometimes floors. Metal-faced SIPs (insulated metal panels) dominate larger commercial and industrial projects—warehouses, cold storage, and distribution centers—serving as factory-finished wall and roof cladding attached to a steel frame. Both types arrive pre-cut and engineered, so projects range from custom homes and multifamily to schools and offices, with hybrid use alongside timber or steel framing when needed.

The big draws are performance and speed. SIPs deliver continuous insulation and very low air leakage, so envelopes hit high R-values and easily meet modern energy codes while improving comfort and reducing HVAC size. Structurally, OSB SIP walls act like diaphragms with high racking resistance; metal panels provide long, strong spans and durable, low-maintenance finishes. Factory fabrication cuts waste, shortens schedules, and reduces on-site labor and trade coordination—benefits that are increasingly valuable amid labor shortages. Sustainability gains come from lower operational energy, efficient use of materials (engineered wood, recycled steel content), and tighter control of moisture and indoor air quality.

Cutting Structural Insulated Panels (SIPs) with ease

SIPs Move Mainstream

Industry growth in Canada and the U.S. is steady as codes tighten and off-site construction scales up. Residential adoption favors OSB/EPS systems for cost-effective, high-performance shells, while commercial expansion is propelled by metal IMPs on logistics, food, and light-industrial buildings. Supply chains have matured—more regional plants, stronger distributor/installer networks, and some vertical integration in foam and panel production—though raw-material volatility (OSB, resins, steel) still influences pricing and lead times. Overall, SIPs are moving from “alternative” to mainstream solutions for high-performance envelopes across both markets.

Effortless processing of Insulated Metal Panels (IMPs)

Why CNC Routing Is Ideal for SIP Production?

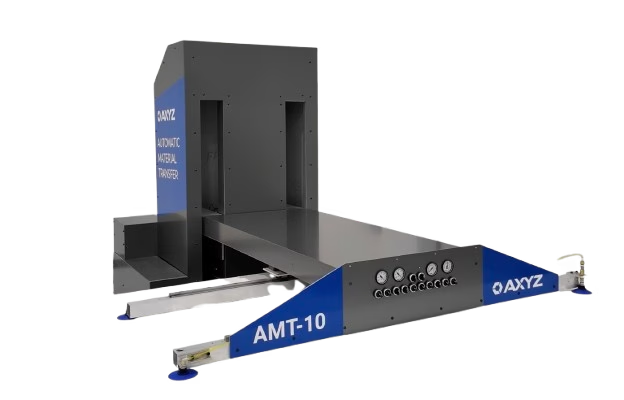

Adding an AXYZ CNC workflow tightens quality and speeds throughput for both OSB and metal SIPs. For OSB SIPs, a saw-equipped gantry lets you tailor the machine to any sheet size—including standard 8 × 24 ft panels—so you can square, trim, and break down jumbos with minimal handling. Quick edge profiling produces consistent spline rabbets and shiplaps in one pass, while the router handles precision cutouts for windows, doors, service chases, and electrical inserts with repeatable tolerances that reduce rework on site. Integrated dust extraction (and chip management for metal) keeps the bed clean, protects finishes, and shortens cleanup time, improving uptime and operator safety. Finally, automated material loading with the new LoadLine series streamlines changeovers on heavy panels, reduces labor and ergonomic risk, and boosts overall panel-shop productivity.